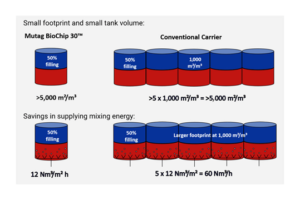

Transcend CleantecPvt Ltd is the supplier of specialized and patented high-performance MBBR media, bio media,/fab media/ reactor media called TRANSCHIP. Transcend Cleantecpvt Ltd has an exclusive agreement with MUTAG GERMANY AND is a well recognized name as a supplier and distributor of quality MBBR media, with its business operations running from Pune, India. TRANSCHIP is available in two diff types : Virgin PE and recycled PE alternative. Removal rates of Transchip are upto 13 times higher than with other “conventional” carriers. The Transchip is a high performance MBBR carrier and provides a protected active surface area of aprrox 5,500 m2/m3 for the immobilization of micro organisms which are in charge of the different biological water treatment processes. Its application is characterized by extremely high removal rates and reliable process stability. The pores of the TRANSCHIP are permanently filled with active biomass since substrate and/or oxygen can diffuse into the biofilms down to a depth of approx. 0.5 mm on both sides of chips.

The MBBR media system is appraising a biofilm process. Other conventional biofilm processes for wastewater treatment is also known as trickling filter, rotating biological contactor (RBC) and biological aerated filter (BAF). TRANSCHIP MUTAG MEDIAprocedure in commonneeds less space than activated sludge structures because the biomass is more focused, and the efficiency of the system is less dependent on the final sludge partition. A disadvantage with other biofilm processes is that they experience bio clogging and a build-up Microbial loss.

Enquiry Now| Surface Area | 5500 m2/m3 |

|---|---|

| Height | 1.1 mm |

| Diameter | 30 mm |

The particularfunctionality as well as the efficiency of the Mutag BioChip 30™ canbe explained bestby orientating on the characteristic MBBR process conditions (MBBR = moving bed biofilm reactor). A crucial prerequisite for the biological removal of wastewater components in the MBBRprocess is the immobilisation of the microorganisms on the surface of carrier elements. Here,the efficiency of the biological removal is determined by the carrier’s “active” surface area. This comes along with the following carrier requirements: Firstly, there must be available sufficient protected effective surface area in order to enable the microorganisms to survive and to reproduce themselves in these areas; and secondly, it is necessary to realise a maximum of mass transfer (substrate, oxygen, metabolic products) between microorganisms and wastewater. At first glance,the simultaneous fulfilling of both of these requirements seems to be a procedural contradiction, but this can be disproved as follows:

Of course, any theoretical considerations require the verification of the projectedbenefits within a confidence-building time frame. So far, we are able to fall back on eightyears worth of operational experience with the Mutag BioChip 30™ and its predecessor Mutag BioChip ™; during thistime it was possible in some cases to operate systems in parallel in order to compare the Mutag BioChip™with “conventional” carrier media. Unfortunately, not all operational results can be listed at this point, as this would understandably exceed the scope of this article. However, on the basis of the selected case examples, it is possible to meaningfully document the efficiency of the Mutag BioChip™. We consider it important to point out that the results listed herein are of fundamental nature, allowing transferring them to other types of wastewater and treatment applications.