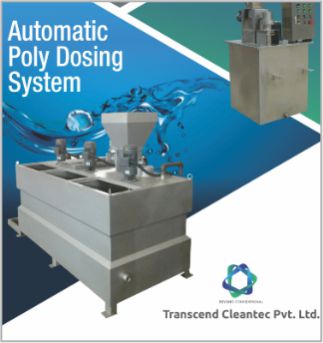

Automatic Poly Preparation and Dosing System

The automatic polyelectrolyte preparation and dosing system consists of a rectangular tank divided into three compartments

First compartment, for dilution, is complete with polyelectrolyte loading hopper, micro-screw dispenser and relevant variable speed drive, fast mixer for the polyelectrolyte mixing, inflow system for the dilution water and solenoid valve, flow meter. The mixing chamber with the a vigorous flow of water starts the initial mixing.

Second compartment,for the polyelectrolyte mixture maturation & homogenization, is equipped with slow mixer and bottom suction and drain system

The third compartment, for maturation and storage, is used for storing the mixture. It is provided with a slow mixer, suction and delivery system for the polyelectrolyte solution.

Every mixer has two impellers fitted on its shaft, each one with four sloping blades. The polyelectrolyte preparation happens automatically: in fact, once the concentration (from 0.05% to 0.5% by weight) has been established, the dosing of dilution water and polyelectrolyte starts automatically. The solution at the TADPS outlet can be further diluted, if required.

The preparation unit is provided with alarms activated by the failure of the dosing screw or shortage of dilution water, insufficient level of polyelectrolyte in the hopper, faulty operation of the stirrer. The powder dispenser is an equipment with a screw and a heater arrangement to remove moisture if any. The standard construction is in stainless steel.

We Supply Automatic Poly Dosing System in UAE, Qatar, Dubai, Oman, Iraq, Mexico, US, Canada, Brazil, Phillipines, Bangladesh, Indonesia, Australia, Malaysia, kenya

Specification :

| POLYMER DOSING SYSTEM | DS CAPACITY (Kgds/h) | POLYMER PUMP - FLOW & HEAD |

|---|---|---|

| AUTO POLYMER DOSING | ||

| TAPDS-250 | 1-3 | 0-20L/h P-1.0MPa |

| TAPDS-500 | 5-7 | Q=30L/h P=1.0MPa |

| TAPDS-500 | 10-14 | 0-50L/h P=1.0MPa |

| TAPDS-500 | 20-28 | Q-100L/h P-1.0MPa |

| TAPDS-500 | 15-20 | Q-90L/h P-1.0MPa |

| TAPDS-500 | 30-40 | Q=150L/h P=1.0MPa |

| TAPDS-500 | 45-60 | Q=270L/h P=1.0MPa |

| TAPDS-500 | 50-70 | Q=300L/h P=1.0MPa |

| TAPDS-1000 | 100-140 | Q=600L/h P=1.0MPa |

| TAPDS-1000 | 150-210 | Q-900L/h P=1.0MPa |

| TAPDS-1500 | 200-280 | Q=1200L/h P=1.0MPa |

| TAPDS-500 | 100-120 | Q=300L/h P=1.0MPa |

| TAPDS-1000 | 200-240 | Q=600L/h P=1.0MPa |

| TAPDS-2000 | 300-360 | Q-900L/h P=1.0MPa |

| TAPDS-3000 | 400-480 | Q=1200L/h P=1.0MPa |

| TAPDS-1000 | 130-160 | Q-900L/h P=1.0MPa |

| TAPDS-2000 | 260-320 | Q=1.8m3/h P=1.0MPa |

| TAPDS-3000 | 390-480 | Q=2.7m3/h P=1.0MPa |

| TAPDS-4000 | 520-640 | Q=3.6m3/h P-1.0MPa |

| TAPDS-2000 | 260-320 | Q=1.7m3/h P=1.0MPa |

| TAPDS-3000 | 390-480 | Q=3.4m3/h P=1.0MPa |

| TAPDS-5000 | 390-480 | Q-5m3/h P=1.0MPa |

| APDS-7000 | 520-640 | Q=7m3/h P=1.0MPa |

Features :

- Completely automatic operation

- Completely in SS304 construction along with panel

- Three compartments, one for dilution, one for ageing and one for storage

- Perfect polyelectrolyte dilution

- Presence of alarm signals for operation in absolutely safe condition

- Heat element avoids chocking of the mixing chamber

- VFD based adjustments to get homogenius and continuous solution with optimum chemical consumption

- Models from smallest size of 250 litres to 7000 litres

- Can adopt to screw dosing pump, diaphragm dosing pump, piston dosing pumps

- Manless operations so error-less operation