STP Plant Manufacturer

Transcend Cleantec Private Limited has pioneered the technique of manufacturing STP (Sewage Treatment Plant) in India.

What is sewage?

Sewage Treatment Plants (STP) are essential for treating wastewater and removing contaminants from it. They are designed to reduce the amount of organic matter, suspended solids, and other pollutants in the water before it is discharged into the environment. STPs are used to treat both domestic and industrial wastewater, with different processes employed depending on the type of wastewater being treated. By using an STP, wastewater can be safely returned to nature without causing any harm to the environment.

Advantages of a Sewage Treatment Plant

Sewage treatment plants (STPs) are essential for the health of our environment and our communities. STPs play a key role in reducing water pollution by treating wastewater before it is discharged into rivers, lakes, or oceans hey also help to reduce the spread of diseases caused by untreated sewage.

A Sewage Treatment Plant (STP) is a facility designed to treat wastewater generated from domestic, commercial, and industrial sources. The primary goal of an STP is to remove contaminants and pollutants from sewage to produce treated water that is safe for disposal or reuse, and to also manage the sludge generated during the treatment process.

Enquiry NowEnvironmental Protection: STPs play a vital role in protecting the environment by treating sewage before discharge into water bodies such as rivers, lakes, or oceans. This helps prevent water pollution and minimizes harm to aquatic life and ecosystems.

Public Health Improvement: Treating sewage before disposal helps prevent the spread of waterborne diseases caused by pathogens present in untreated sewage. Treated water can also be reused safely for irrigation, industrial processes, or non-potable purposes, reducing the strain on freshwater resources.

Compliance with Regulations: Many countries have strict regulations governing the quality of wastewater that can be discharged into the environment. STPs help municipalities and industries comply with these regulations, avoiding fines and penalties while maintaining environmental standards.

Odor Control: Proper treatment of sewage in STPs helps control foul odors associated with untreated sewage, improving the overall quality of life for nearby residents and reducing complaints related to odor pollution.

Resource Recovery: STPs often incorporate processes for the recovery of resources such as biogas (from anaerobic digestion of sludge) and nutrient-rich biosolids (from sludge treatment). Biogas can be used for energy generation, while biosolids can be reused as fertilizers in agriculture, promoting circular economy principles.

Reduced Impact on Water Bodies: By treating sewage before discharge, STPs reduce the biochemical oxygen demand (BOD) and nutrient levels in wastewater. This helps prevent eutrophication of water bodies, which can lead to algae blooms and oxygen depletion, negatively impacting aquatic ecosystems.

Sustainable Practices: Implementing STPs aligns with sustainable development goals by promoting responsible water management, resource recovery, and pollution prevention. It supports efforts to achieve water conservation and environmental sustainability.

Long-term Cost Savings: While there are initial investments involved in setting up and operating STPs, they can lead to long-term cost savings by reducing the need for freshwater intake, lowering wastewater disposal costs, and avoiding potential environmental cleanup expenses associated with untreated sewage discharge.

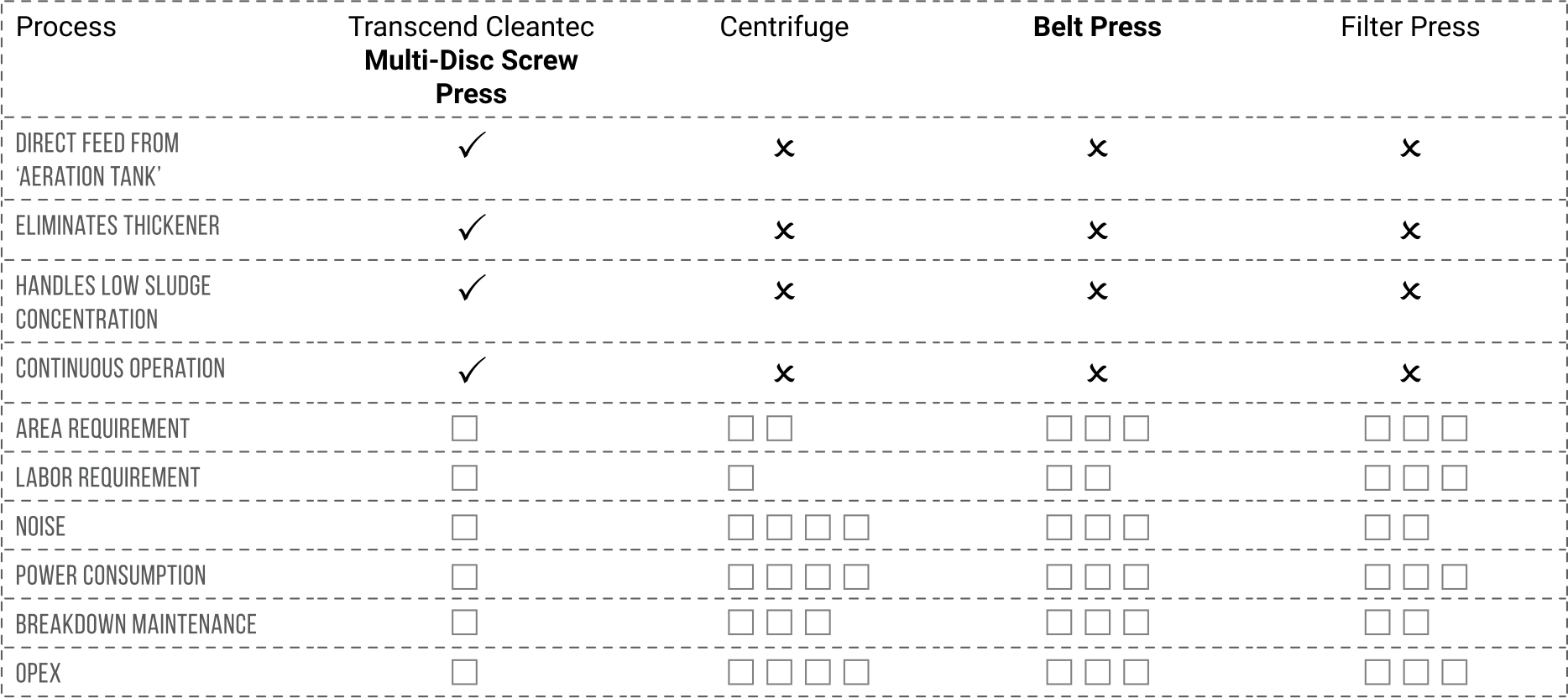

The conventional sludge dewatering systems like centrifuges, Belt press, Filter press (Plate & Frame type) have many draw backs. The drawbacks include-

- Large foot print

- High power consumption

- High Operational cost / consumables

- Frequent breakdown

- Non-continuous (batch) operation

- High maintenance requirement

- Multiple Pretreatment

- High labor

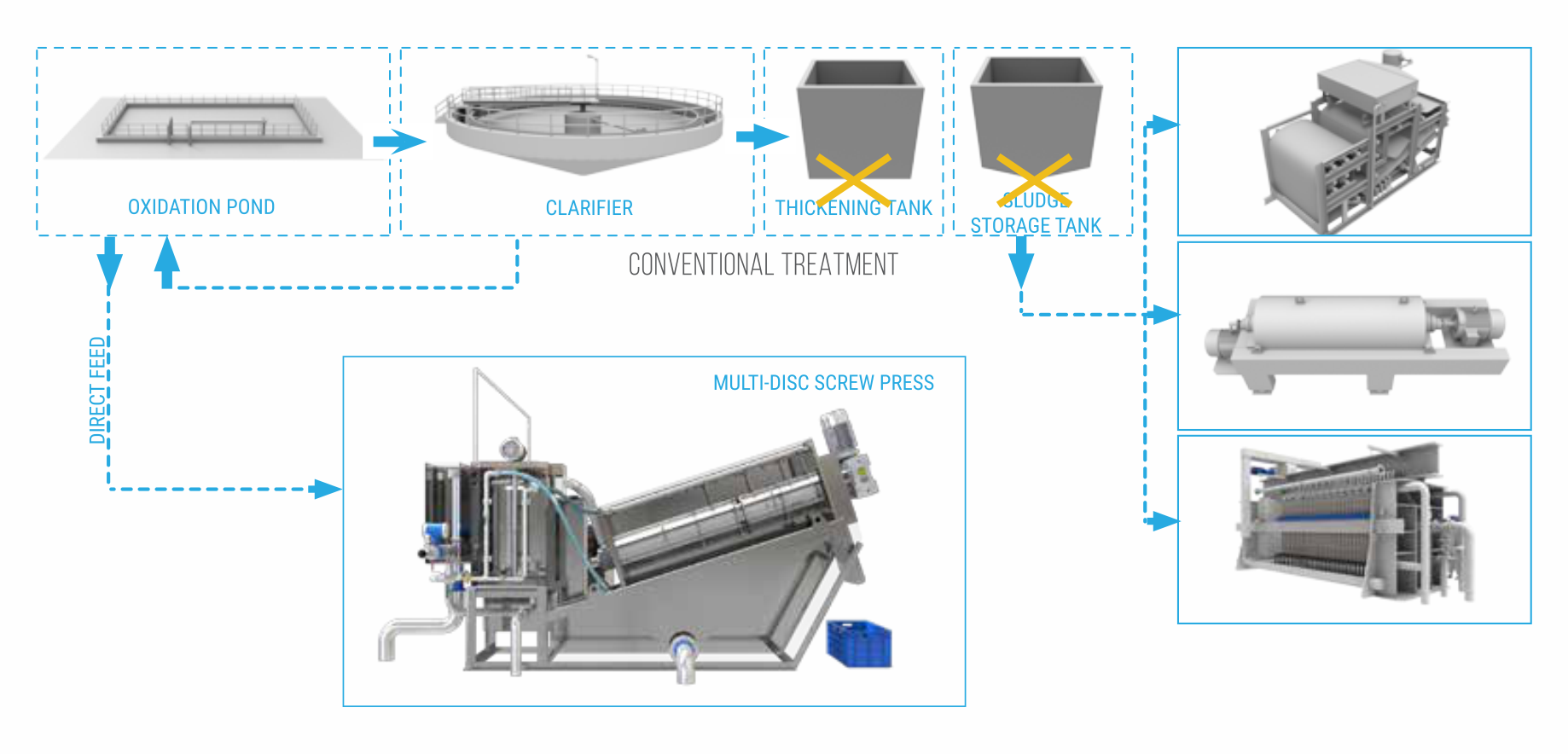

As the Multi-Disc Screw Press can take the load directly from the oxidation ditch, considerable capital cost, construction costs and maintenance cost can be avoided

DIRECT DEWATERING FROM OXIDATION DITCH

Feed sludge directly from the oxidation ditch / aeration tank. This eliminates the need to construct settling tanks, sludge thickener or sludge feed tanks. This advantage leads to a good reduction in CAPEX as well as OPEX.

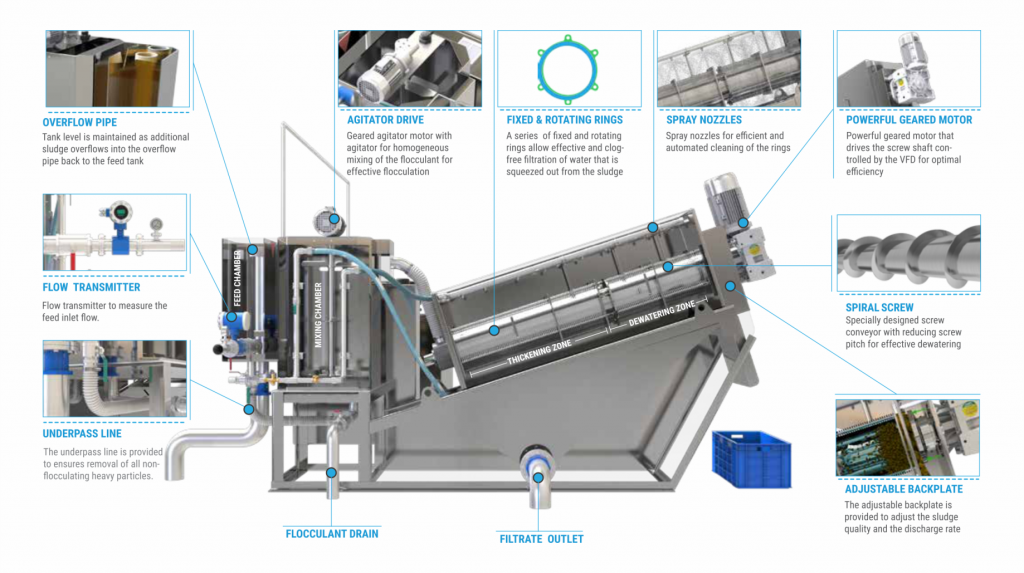

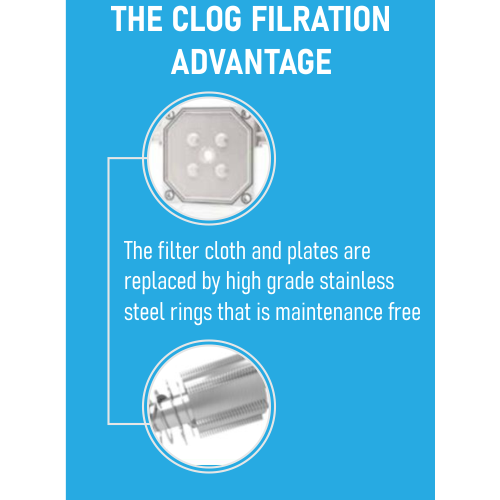

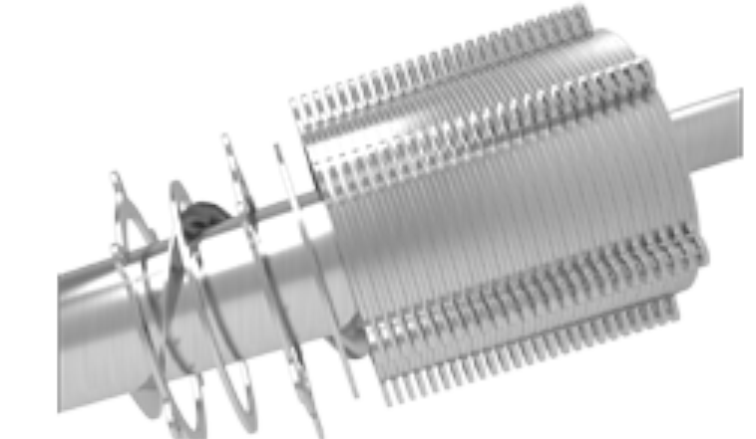

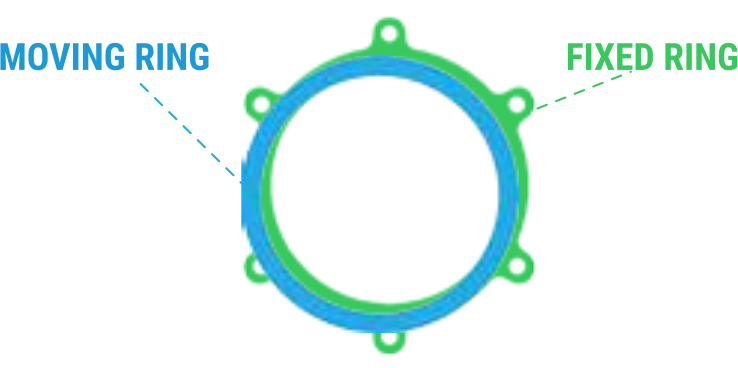

CLOG FREE DESIGN

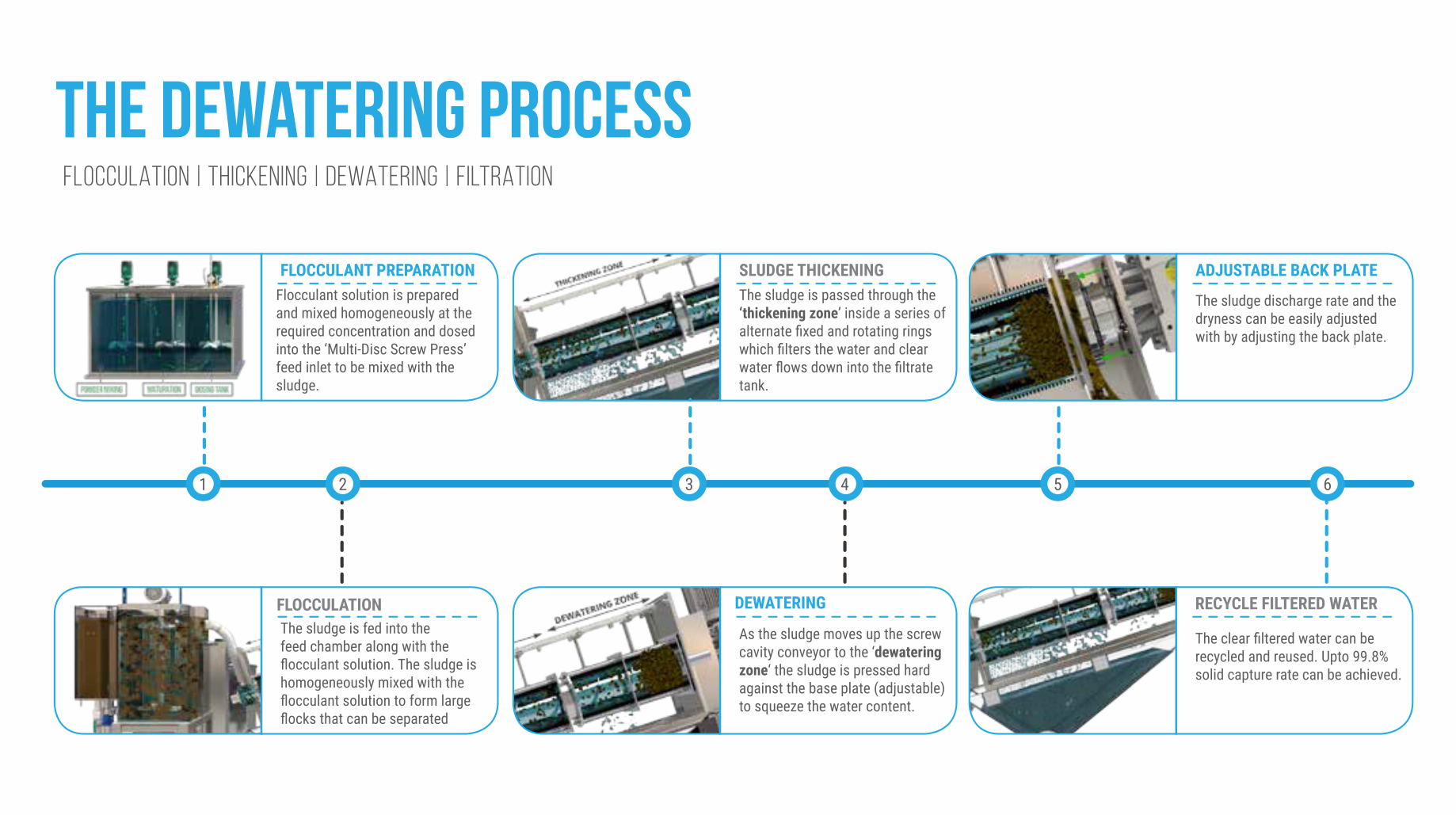

The series of heavy duty finely machined fixed and rotating rings placed alternately provides efficient filtration that remains clog free due to the continuous movement of the rings. This eliminates the need for consumables like filter cloth etc

FULLY AUTOMATIC

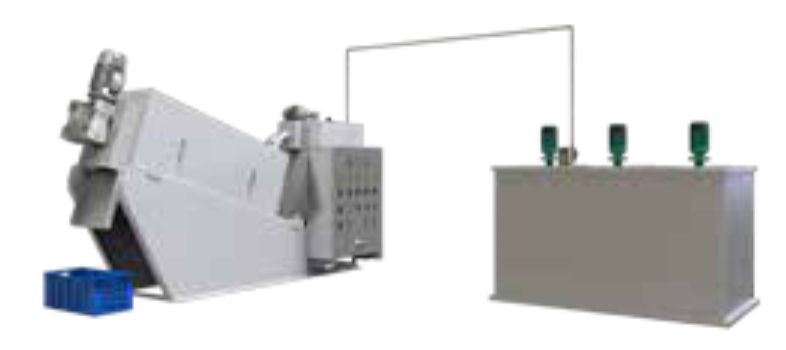

The system can be fully automatic with PLC controls. Option of variable frequency drive (VFD) is available to control the dosing and the screw speed to automatically adjust to the varying loads of the effluent. The system can run continously, unmanned.

LOW CAPEX

The system can take sludge directly. This eliminates the need to build sludge thickening tank and sludge storage tank, thereby saving on space and civil construction costs.

ODOURLESS PROCESS

Since both the sludge thickening tank and the sludge storage tank is eliminated and as sludge is not stored for long periods of time, there is no anaerobic process happening. This eliminates the possibility of unpleasant odour.

HANDLES OILY SLUDGE

Due to the rotation of the helical axis, the moving rings detach from the fixed rings while continuous- ly cleaning itself. As a result clogging is avoided. Therefore it can easily handle oily sludge.

LOW OPEX

The system works on its internal pressure. It saves energy due to its low running speeds (2-4 rpm). The average power consumption is only 0.01 – 0.1 kw/h which is 12% of a belt press and 5% of a centrifuge

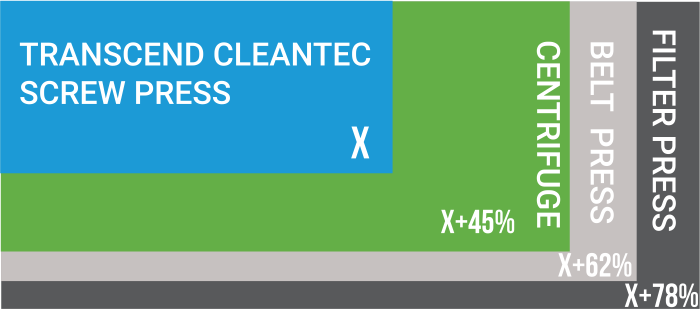

SMALLEST FOOTPRINT

The Transcend Cleantec Screw Press takes the least space among other technologies. Its approximately 45% less space than Centrifuge, 62% less space than Belt Press and 78% less space than Filter Press of conventional design.

CAPACITY & SCALABILITY

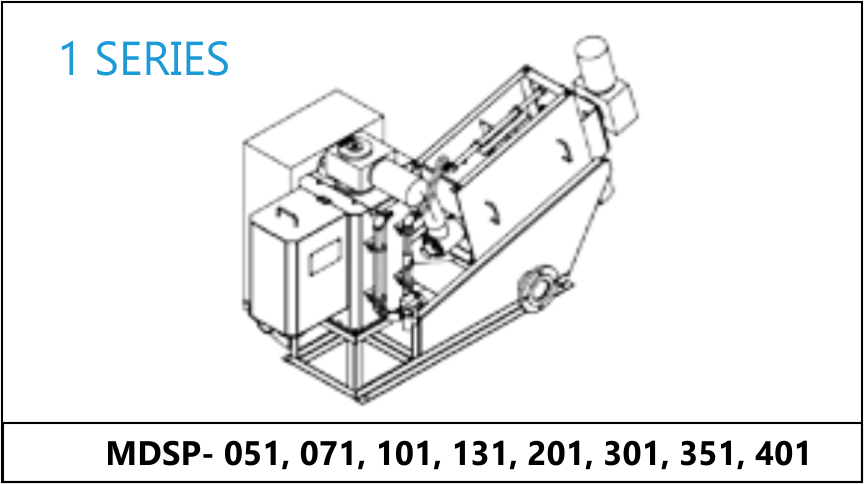

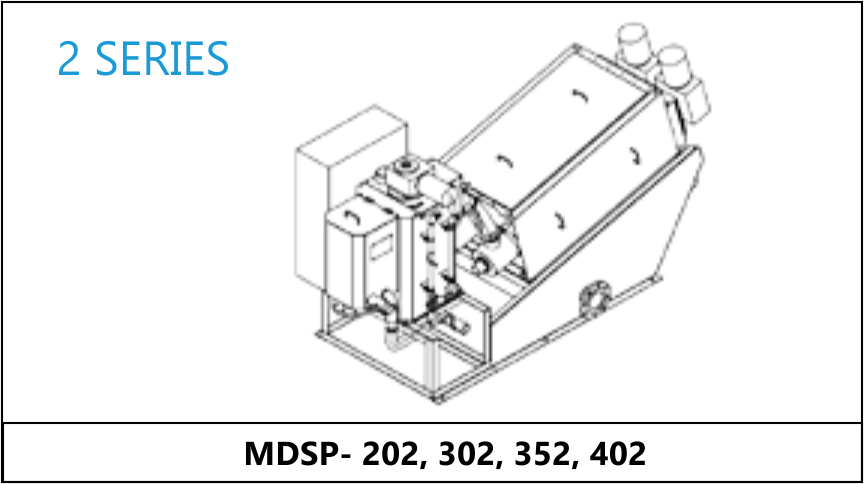

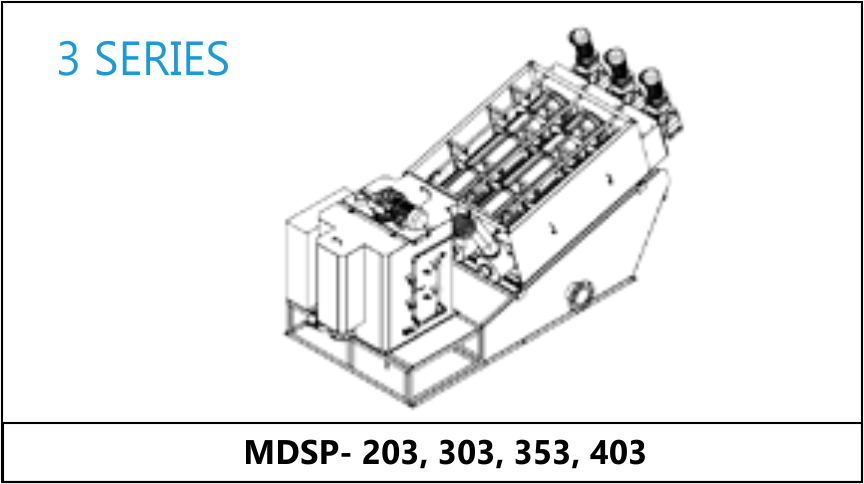

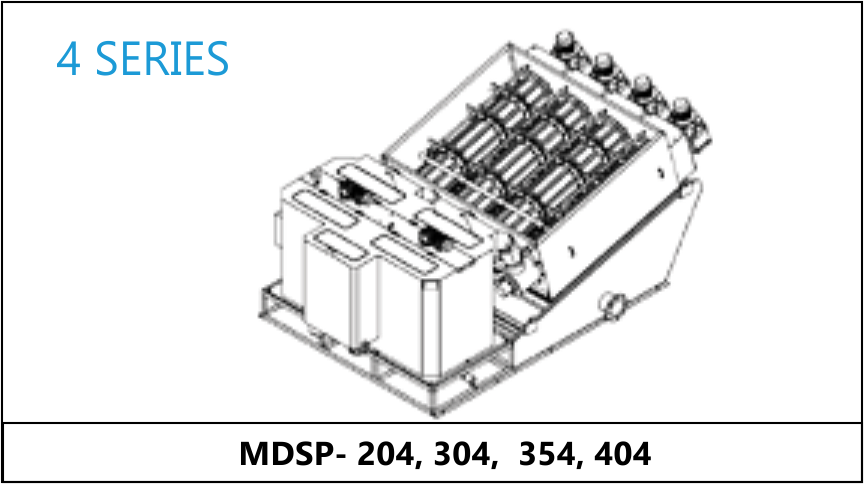

Transcend Cleantec Multi Disc Screw Press is designed to cater to various capacities. Systems are available from 0.2 m3/hr – 133.5 m3/hr (@0.2%sludge conc.) Due to its modular design and compact construction, the capacities can be easily scaled up by running systems in parallel to cater to almost any capacity as required and as and when required. We can also optimize the design for cost and efficiency based on your custom requirement using the standard models.

INSTALLATION, SERVICE SUPPORT & TRAINING

Our experienced and trained team of engineers help you with the installation and operator training. Our systems are designed to be a work horse and run for years without needing any service. But there are odd chances that you may need service support. Our trained technicians are an email or call away. With adequate training and spares at their disposal, they will ensure the system is up and running in a very short time.