Disc Filter Manufacturer

Transcend Cleantec has pioneered the technique of manufacturing disc filter in India and Disc Filter supply in UAE, Qatar, Dubai, Oman, Iraq, Mexico, US, Canada, Brazil, Phillipines, Bangladesh, Indonesia, Australia, Malaysia, kenya, India.

“DISC FILTER" innovation in tertiary water treatment

Our company, Transcend Cleantec has specialized in the production of Disc Filter, waste water treatment systems for over 10 years. We have used all of our knowledge and experience in filtration to enhance our product portfolio. So after years of development and trials we bring you our innovation. It brings a new filtration possibilities for your tertiary treatment applications.

Size and series

Disc Filter - For greater variability and adaptation to the capacity needs of each project & application TCPL TEAM has developed four size series of Disc Filter.

After long-term testing, we offer smaller compact filter with a diameter of 1m, medium sized device with a diameter of 1.5 & 2m, and the biggest sized device with a diameter of 3m providing the biggest filtration area and capacity.

Design and properties

- To ensure the highest standards in waste water treatment technology we use only quality materials

- Filter cloth is available with mesh opening sizes ranging from 5 μm to 50 μm.

- 100% submerged design in combination with increased filtration surface for higher capacities.

- TSS removal, Preduction, BOD and COD partial reduction is a great solution for the micro-pollutants removal applications

- The non metallic chain doesn't need any lubrication

- Design of the shaft and its fixing provides extraordinary long sealing life.

Out to in system

This type of filtration comes with 100% immersed disc design involving different type of filtration cloth than used on conventional 65% immersed Disc filters.

Exceptional filtration results can be achieved even with the combination of TCPL filters.

DISC FILTER – for efficient TSS removal

With increasing water crisis, irregular rain patterns, high density populated cities, water recycling efficiently is on the rise. Added to this NGT has raised the regulations of outlet norms for STP. Older plants in such scenario are getting notices from statutory bodies like pollution control boards to comply to new norms..

Disc filter comes as a preferred solution due its stand-alone installation outside the STP without any interruption to achieve desired levels in combination with MBBR. Disc filters are designed for tertiary treatment of municipal and industrial waste water bur not restricted to these applications.

We developed disc filter with knowledge and experience acquired in last twenty five year’s experience in water & waste water industry.

We Supply Disc Filter in UAE, Qatar, Dubai, Oman, Iraq, Mexico, US, Canada, Brazil, Phillipines, Bangladesh, Indonesia, Australia, Malaysia, kenya.

Nano |

Small |

Medium |

Large |

Extra Large |

|---|---|---|---|---|

• Disc diameter 1m |

• Disc diameter 1.5m |

• Disc diameter 1.5m |

• Disc diameter 2m |

• Disc diameter 3m up to 32 discs |

• up to 14 discs |

• up to 14 discs |

• up to 20 discs |

• up to 32 discs |

• ideal for large and even larger capacity |

• ideal for small capacity |

• ideal for small to medium capacity |

• ideal for small to medium capacity |

• ideal for medium to large capacity |

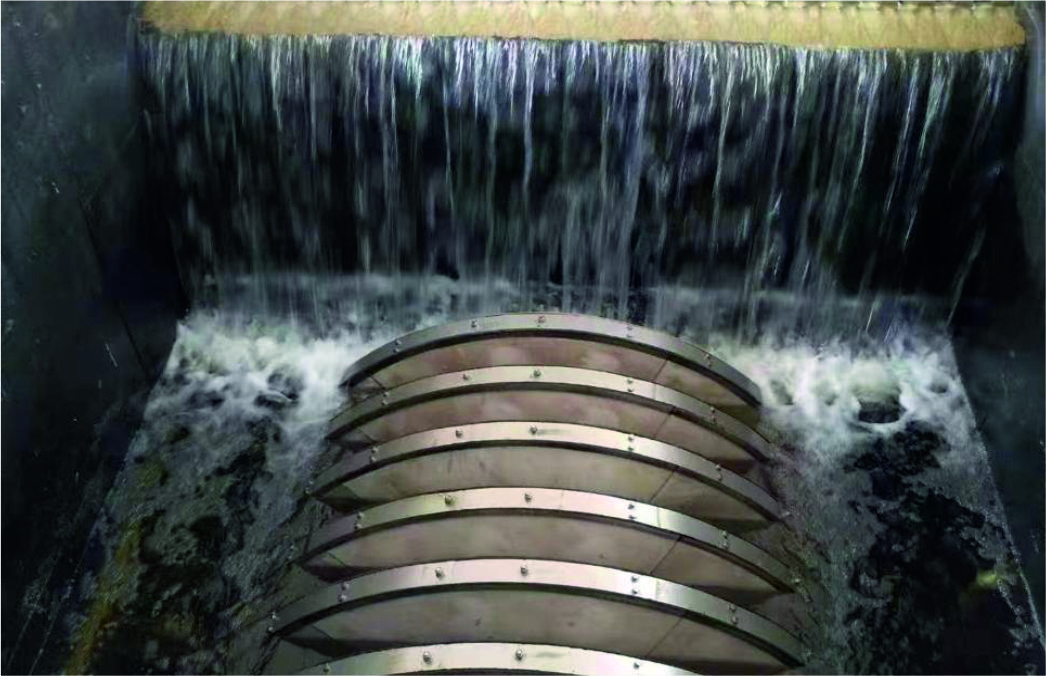

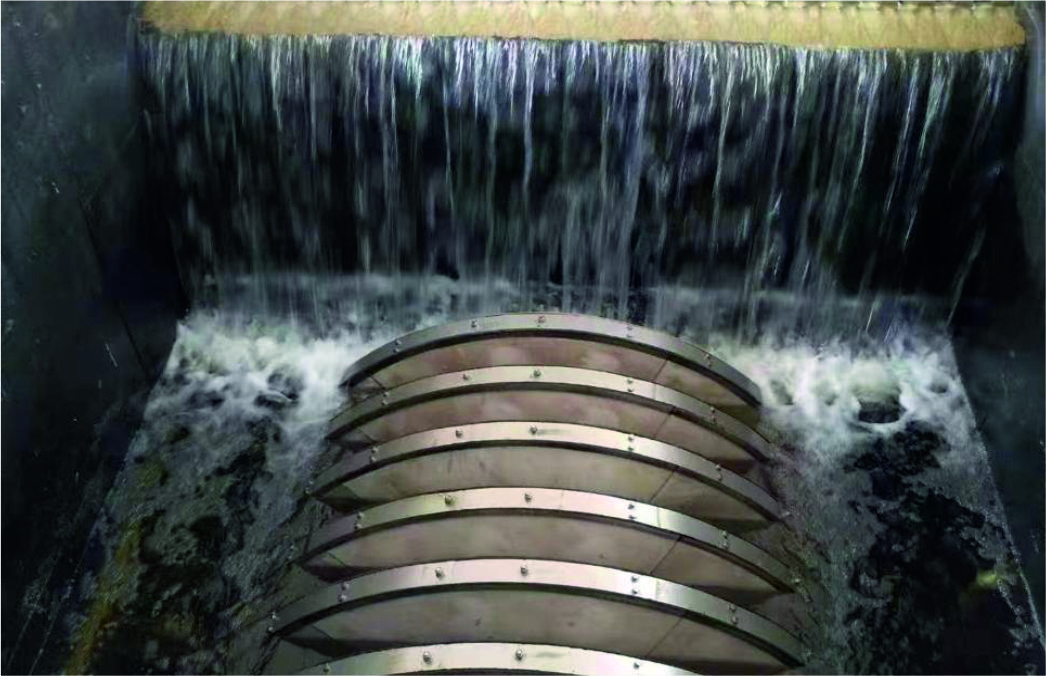

Functioning of Disc Filter

Disc filters are high flow rate in to out filtration systems. Mostly the water flows into the discs through central drum and out from the discs. We make discs from woven cloth fabric that holds solids from the water. We use cloth filters mounted on multiple discs providing a large filtering area in a small footprint. The water to be treated flows by gravity into the discs through drum centre and passes through the filter cloth on both sides of the discs. The solids are captured within the discs cloth and the filtered water flows to the tank.

The filter assembly is idle at the beginning of the filter cycle, it does not rotate. TSS larger than the degree of filtration are arrested on the inner side of the filter. As the TSS is arrested on filter cloth, the flow decreases and the water level in the disc drum increases gradually. Slowly due to rising TSS water starts logging triggering a level sensor automatically to backwash the filter.

When the water level sensor is activated, the filter discs starts to rotate and initiates backwash. High-pressure backwash nozzles push the arrested TSS particles towards the sludge trough. As the water level decreases to the pre-set minimum level and the backwash cycle ends, the unit stops rotating filtration cycle returns to its maximum capacity at minimum level. The filtration cycle keeps on repeating. Filtration goes on continually without interruption. Due to efficient and Realtime backwashing, full capacity of the filter is maintained all the time.

Our disc filter offer better TSS removal, flexibility from smallest size to highest size, modular design to economise the installation, local support, easy to maintain with convenient efficient cleaning and options for variety of degree of filtration. In addition to this, our compact design & high filtering area makes it the ideal solution for polishing of wastewater, recirculation systems, fine filtration of water treatment.

Advantages of TCPL Filters

- Continuous filtration even during the backwash

- High capacities on small footprint (100% submerged)

- Higher filtration area per disc

- Lower power consumption during backwash

- Low operational cost

- Possibility of sedimentation in the filter pit

- No aerosol pollution during backwash cycle

- Exceptionally low noise pollution

- Long span life of filtration cloth - doesn't threat to tear the cloth

- 2.2 m diameter with 1m² more of filtration surface area, than available until today on the market.

Tertiary treatment

- Treatment of effluent water

- Pretreatment before UV

- Pretreatment of potable water

- Fish farms and Koi ponds

- Paper industry

- Cooling water in various industries

- Inlet process water

- Food processing

- Recovery of valuable materials in different types of industry

Benefits for customers

- Higher quality of effluent water

- Great solution for industrial applications

- Gravity flow saves energy costs

- Exceptionally low power consumption

- Filters can be adjusted to suit customer's needs/project

- Possibility to combine with woven cloth Disc filters at two-stage filtration systems

- Low maintenance costs

- The unit can be put into operation immediately after its installation

- Better resistance to handle the influent imbalances/peaks

For the right filter size it is necessary to take into consideration the maximum influent hydraulic flow(Qmax),the expected loading and particle size of suspended solids(SS),and then mesh size in combination with surface loading to achieve the best effluent water quality

Optimal operation of multiple filters can be managed in parallel by a PLC or other computerized system.

The filter can be different in a concrete channel version or steel tank version

We also offer different optimal accessories to TCPL filters such as covers,overflow pipe emergency overflow,etc.

DISC DIA 1500MM

MODEL |

CAPACITY |

DISC |

DISC |

POWER |

TDF 1500-2 |

500 |

1500 |

2 |

0.55 |

TDF 1500-4 |

1000 |

1500 |

4 |

0. 75 |

TDF 1500-6 |

1500 |

1500 |

6 |

0. 75 |

TDF 1500-8 |

2000 |

1500 |

8 |

0. 75 |

TDF 1500-12 |

3000 |

1500 |

12 |

1.5 |

TDF 1500-18 |

4500 |

1500 |

18 |

1.5 |

TDF 1500-28 |

7000 |

1500 |

28 |

3 |

TDF 1500-34 |

8500 |

1500 |

34 |

3.5 |

TDF 1500-40 |

10000 |

1500 |

40 |

3.5 |

DISC DIA 2000MM

MODEL |

CAPACITY |

DISC |

DISC |

POWER |

TDF 2000-2 |

1000 |

2000 |

2 |

0.55 |

TDF 2000-4 |

2000 |

2000 |

4 |

0. 75 |

TDF 2000-6 |

3000 |

2000 |

6 |

0. 75 |

TDF 2000-10 |

5000 |

2000 |

10 |

1.1 |

TDF 2000-12 |

6000 |

2000 |

12 |

1.1 |

TDF 2000-18 |

9000 |

2000 |

18 |

1.5 |

TDF 2000-24 |

12000 |

2000 |

24 |

2.2 |

TDF 2000-30 |

12000 |

2000 |

30 |

3 |

DISC DIA 3000MM

MODEL |

CAPACITY |

DISC |

DISC |

POWER |

TDF 3000-1 |

1000 |

3000 |

1 |

0.75 |

TDF 3000-3 |

3000 |

3000 |

3 |

1.1 |

TDF 3000-5 |

5000 |

3000 |

5 |

1.1 |

TDF 3000-9 |

9000 |

3000 |

9 |

1.5 |

TDF 3000-11 |

11000 |

3000 |

11 |

2.2 |

TDF 3000-16 |

16000 |

3000 |

16 |

2.2 |

TDF 3000-23 |

23000 |

3000 |

23 |

3.5 |

TDF 3000-29 |

30000 |

3000 |

39 |

3.5 |

NOTE..

- Above is our standard model, dia , pcs & mesh of disc can be customized according to your site capacity as well.

- Small capacity can be made with integrated steel tank at our factory.

- Civil tank is necessary for larger capacity

Selection process

For the right filter size it is necessary to take into consideration the maximum influent hydraulic flow (Qmax), the expected loading and particle size of suspended solids (SS), and then mesh size in combination with surface loading to achieve the best effluent water quality.

Optimal operation of multiple filters can be managed in parallel by a PLC or other computerized system.

The filter can be supplied in a concrete channel version or steel tank version.

We also offer different optional accessories to TCPL filters such as covers, overflow pipe emergency overflow, etc.