Moving Bed Biofilm Reactor

Transcend Cleantec is the best MBBR technology manufacturer and Supplier in Pune, India. Moving bed biofilm reactor (MBBR) is a biological technology used for wastewater treatment process suitable for urban and industrial application. Another common name is moving bed film reactor. It was invented in the 1980s. MBBR offer an economical solution for wastewater treatment. STP MBBR technology is the used in sewage treatment plants.

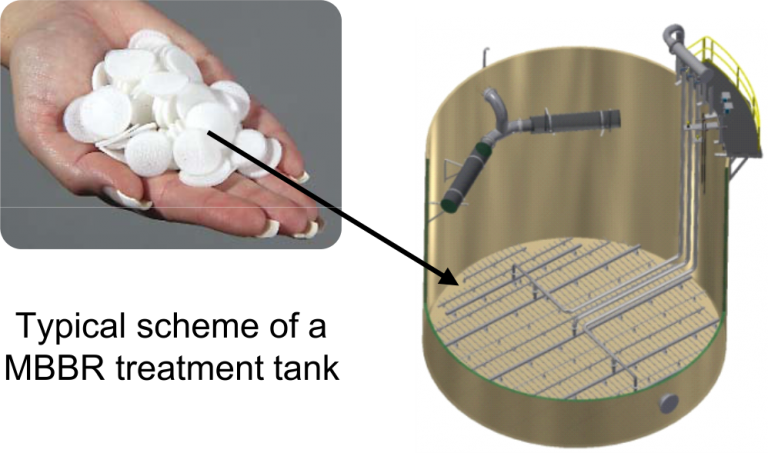

MBBR technology employees thousands of polyethylene biofilm carriers working in mixed motion within an aerated wastewater treatment basin. Each specific bio carrier expands manufacturing through supply a protected surface area to support the progress of heterotrophic and autotrophic microorganisms within its cells. It is this high-density population of bacteria that execute high-rate biodegradation within the system, while also offering process consistency and ease of operation. MBBR wastewater treatment system allows efficient results of the disposal using low energy. This technology is used to separate organic substances, nitrification and DE nitrification. MBBR design is made of triggered sludge aeration system. The sludge is collected on the plastic carriers, which have a big internal surface area. The surface area in the carriers improves the contact of water, air, and the bacteria.

MBBR activated sludge is the application of MBBR media to an overloaded treatment plant when update. MBBR is appropriate to the different quality of wastewater treatment. The application is determined by the desired results and regulations controlling discharge. The system can be of more than one stage turn on specific needs. The stages are made of individual tanks separated by screens to confirm that bacteria remain in their specific tank. This technology provides cost-effective treatment with minimal maintenance since MBBR procedures self-maintain a best level of productive biofilm. Additionally, the biofilm attached to the mobile bio carriers within the system automatically responds to weight fluctuations.

Industrial Applications

- Capacity increase

- Quality Improvement – BOD & Nitrogen Removal

- Fast recovery from Process Upsets

- Limited Footprint

- Future Expansion

- Minimize Process Complexity and Operator Attention

Benefits

- Economical very attractive

- Compact (saves space)

- Maintenance-friendly

- Strong

- High volume load

- Simply to extend

- Financial savings on discharge costs

Charactristics

1) INCREASE SURAFACE AREA: Larger surface area=potential major bacterial growth in the pores of the carrier media,which results in a higher concentration of biomass that leads to reduced volume requirements

2) REDUCED ENERGY CONSUMPTION: Reduced energy consumption for aeration and mixing(compared with conventional carrier media)

3) SECURITY FOR BIOMASS: Security for the bacteria colnization due to the special surface with high-quality pore system

4) OPTIMAL DIFFSION DEPTH: Control of the biofilm thickness and therefore an optimal diffission depth forsubstrates and oxgyen.No limitation to the biological processes.

5) SLEF-CLEANING: Self-cleaning carrier media which ensures a thin and always active biomass.

6) NO DEAD ZONES: Avoidance of dead zones which means that the entire surface area ia used for the biological processes.

7) LONG LIFE MATERIAL: Paraboloid shape and protection ring ensure no signs of wear and tear. Long lifetime of the material without substitution.

8) EASY RETROFIT & UPGRADE: Ideal to add when there is no prossibility to build new tanks or no space left.All plants are easy to manage and to operate.

9) LOW PROSUCTION OF SLUDGE: Low sludge protection due to thin and controlled biomass.

10) WILD-RANGE APPLICATION: Designed to be used in all biological treatment application

Design & Application Engineering

The Transchip 3.0 MBBR Technology is a proven biological treatment process with numerous WWTP opertors.A lot of plnats using the Transchip 3.0 MBBR Technology have been designed and engineering in basic and details and deatil by Transcend Cleantec's highly-qualified engineering team.

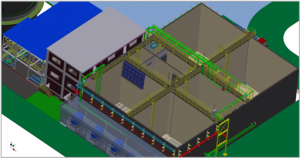

3D-engineering by Transcend Cleantec

3D-engineering by Transcend Cleantec

Trendsetting and sustainable MBBR Carrier technology....

- Pulp & paper industry.

- Munical plants.

- Coke & steel productions.

- Petrol and oil industry.

- Food and beverage industry

- Pharmaceutical & chemical industry

- Aquaculture industry and fish-farming

TRANSCHIP 3.0 MBBER Technology

TRANSCHIP 3.0 MBBER Technology

Based on more than 20 years of experience,Transcend Cleantech offers beyound conventional technology for biological treatment.

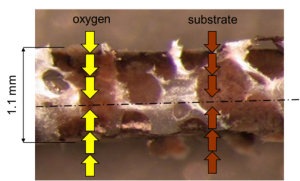

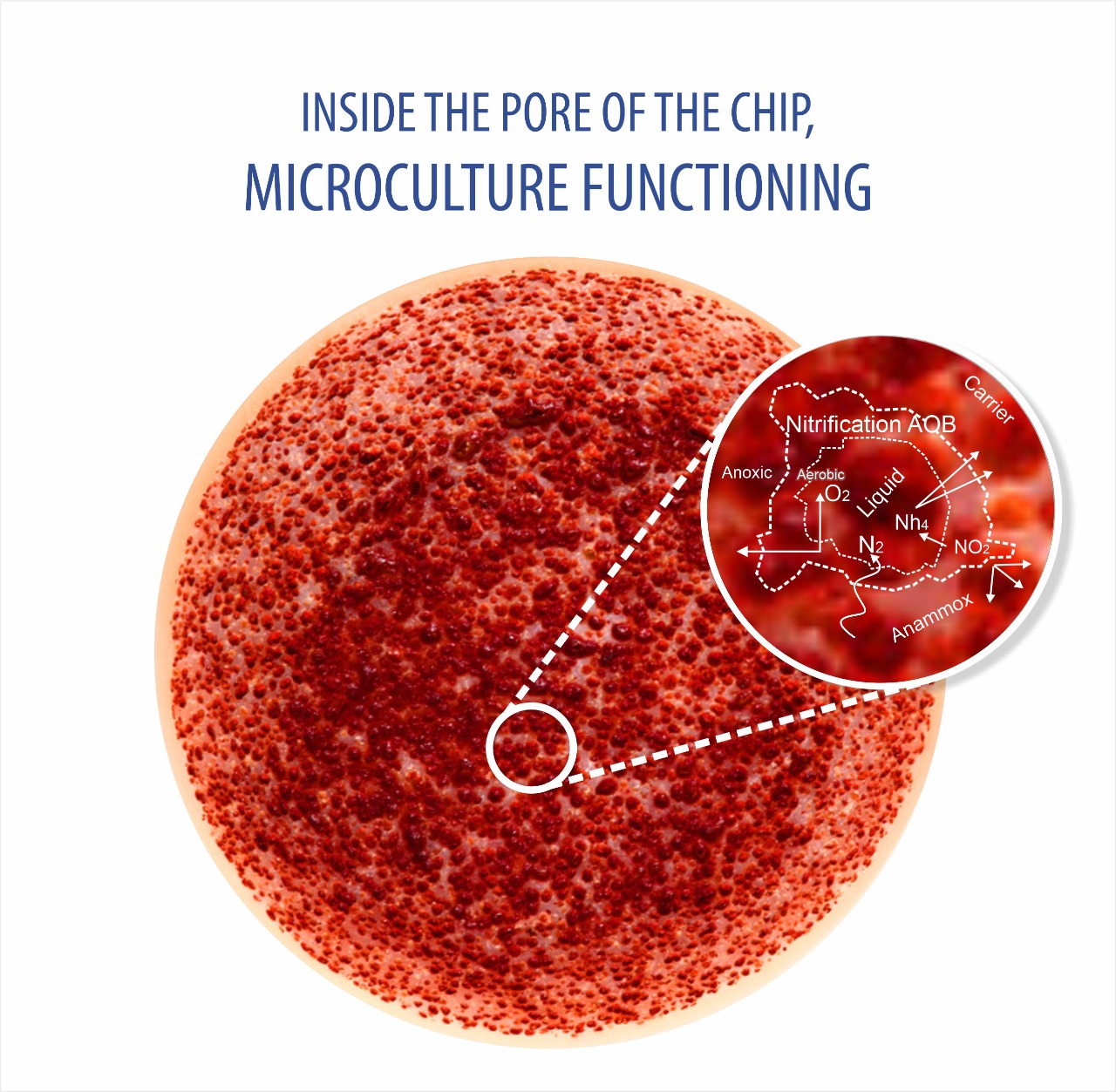

The pores of the Transchip 3.0 are permanently filled with active biomass since substate and/or oxygen can diffuse into the biofilms down to a depth of approx 0.5 mm on both sides of the chips.

High quality pore system of TRANSCHIP 3.0

High quality pore system of TRANSCHIP 3.0

System Components

TRANSCHIP 3.0 with biofilm

TRANSCHIP 3.0 with biofilm

Aeration System

Aeration System

Carrier retetion screen

Carrier retetion screen

Micro Culture Functioning

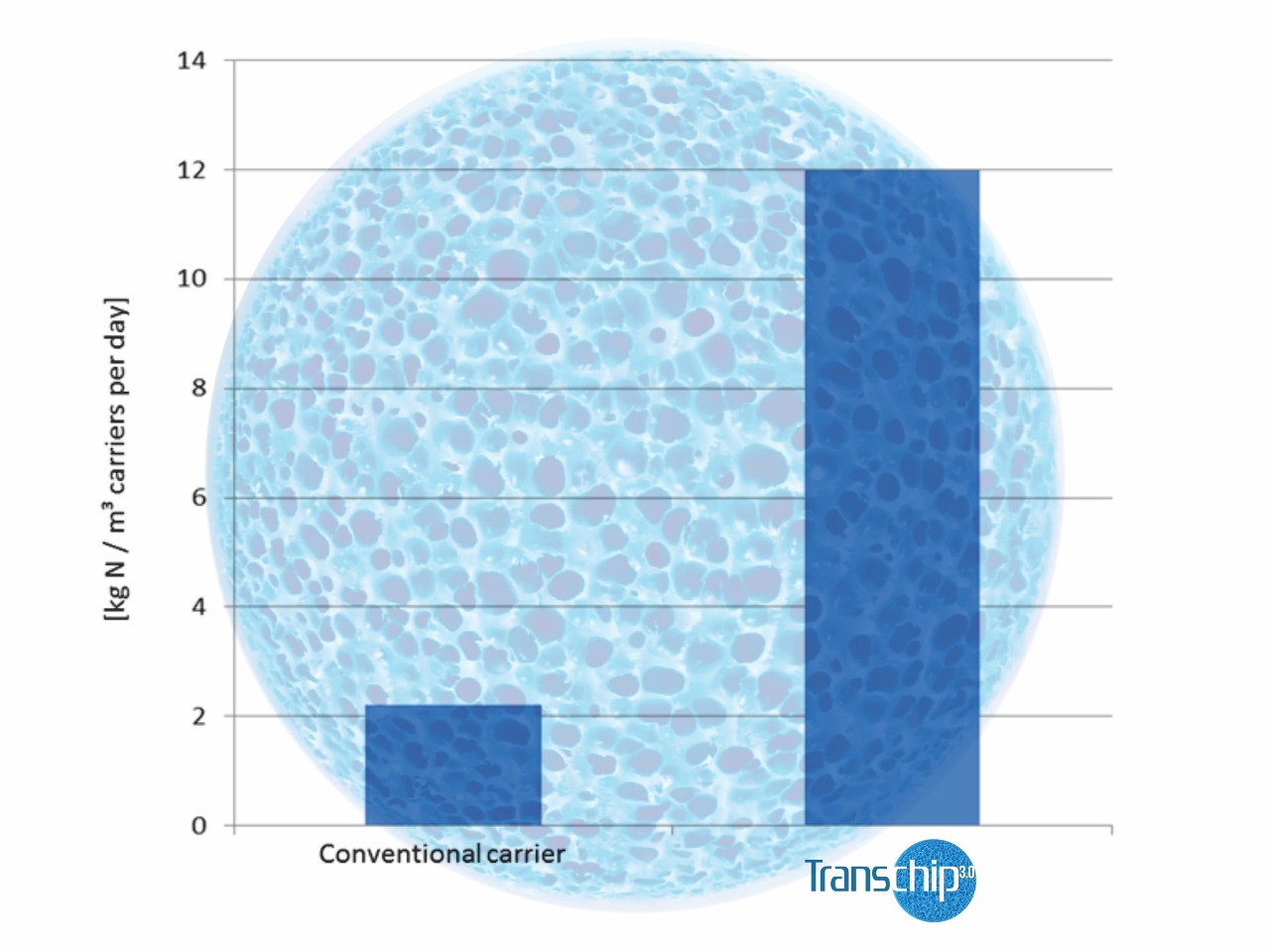

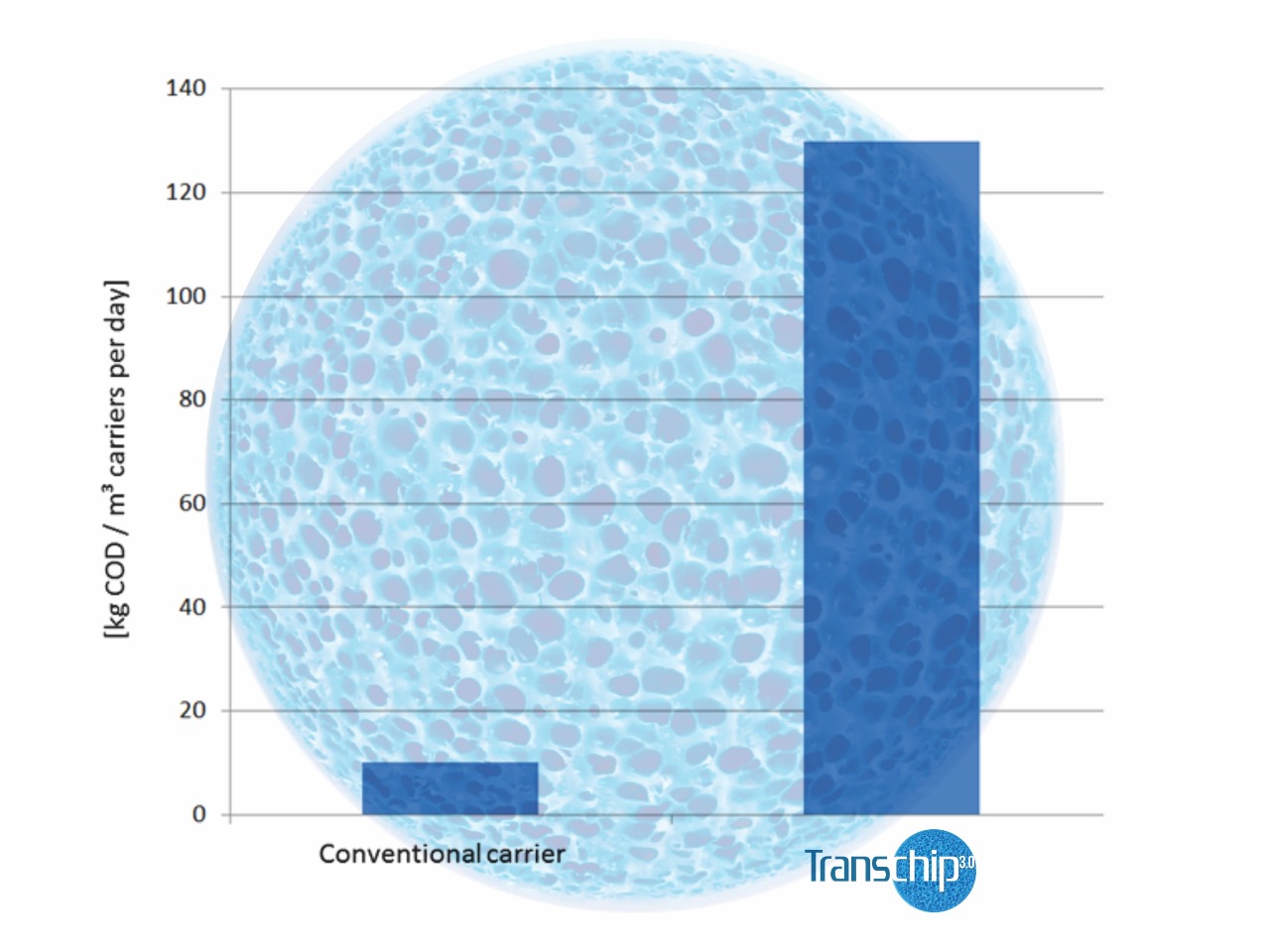

BOD,COD and Nitrogen Removal Rate

[kg N/m3 carriers per day]

[kg N/m3 carriers per day]

[kg COD/m3 carriers per day]

[kg COD/m3 carriers per day]

Advantages of Transchip 3.0 and Ecochip 3.0

- Protected active surface area: ~5,500 m2/m3

- High quality PE material(virgin).

- Optimal pore system and -structure

- Less carrier volume needed

- Small footprint system

- Simple operation

- Thin,controlled biofilms

- optimal diffusion of O2 and substrate

- Easy upgrading or retrofitting of existing plants

- Large diameter

- No abrasion & wear

- Proven technology & know-how "Made in Germany"

- Extermely high removal capacity due to maximized concentration of active biomass in smallest possible reaction volume

- Process supports for calculations

- Prefectly suitable for the operation with blocking-resistant and large-perforated retention screens(perforation dia.20mm).

- Economical option with regranulated coating also available

For highest performance in biological water treatment

- Best possible removal performance

- REmarkably stable processes

- Small footprints

- High grade quality

- ideal for easy retrofit & upgrade

- Long life material

- No wear & tear

- Best price-performance ratio

The best carrier available

Removal rates of Transchip 3.0 are up to 15 times higher than with "Conventional" carriers.

The Transchip is a high-performance MBBR carrier and provides a protected active surface area of ~5,500 m2/m3 for the immobilization of micro-organisms which are in charge of the different biological water treatment processes.

Its application is characterized by extremely high removal rates and reliable processes stability

TRANSCHIP 3.0

TRANSCHIP 3.0

ECOCHIP 3.0

ECOCHIP 3.0

Diffusion depth from each side approx. 0.5 mm

Diffusion depth from each side approx. 0.5 mm

Transchip 3.0

- Suraface Area - 5500 m2/m3, 6 to 14 times higher than conventional media

- Removal Performance - Less than 10 BOD

- Clogging - Anti clogging design

- Process Stability - Highly stable

- Savings in Construction cosats - 50%

- Ease in upgradation - Very easy, can up,grade to 5 times the load

- Energy savings - About 30 to 50% due to parabolic design and low mixing requirement

- Savings in transportation costs - Yes,it occupies less space per m2 and per m3

- Durability - 20 years guaranteed life.

- Reactor load rate - 3-6% of tank volume for STP

- Other Application - Nutrient removal,Anomox

Conventional Media

- Surface Area - 400 to 500 m2 per m3

- Removal Performance - 30 BOD

- Clogging - Yes,frequently

- Process Stability - Not stable

- Savings in Construction Costs - Not much compared to ASP

- Ease in upgradation - Easy

- Energy savings - Not much

- Savings in transportation costs - No

- Durability - 3 to 5 years

- Reactor load rate - 30-40% of tank volume for STP

Specification Data Sheet

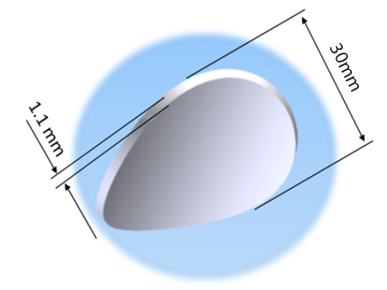

| Product Name | Transchip 3.0 |

| Developer,Manufature,Distributor | Multi Umwelttechnologie AG,Zschopauer Strasse 105,D-09126 Chemnitz(Germany) |

| Description | High-performance biofilm carrier media for immoblilizing microorganisms in biological water treatment plants |

| Applications | COD/BOD removal,nitrification,denitrification,ANAMMOX process |

| Active surface area(protected) | Up to 5,500 m2/m3 |

| Bulk Weight(net) | 165.00 kg/m3 +-2% |

| Color | White |

| Shape | Round,paraboloid |

| Pore system | May vary due to raw material |

| Material | PE virgin material |

| Diameter | 30.0 mm |

| Material thickness | Approx.1.1 mm |

| Specific gravity | Approx.0.95 kg/I(without biofilm) |

| Note | Quality product for optimal biological removal-rates |

Specification Data Sheet

| Product Name | Ecochip 3.0 |

| Developer,Manufature,Distributor | Multi Umwelttechnologie AG,Zschopauer Strasse 105,D-09126 Chemnitz(Germany) |

| Description | High-performance biofilm carrier media for immoblilizing microorganisms in biological water treatment plants |

| Applications | COD/BOD removal,nitrification,denitrification,ANAMMOX process |

| Active surface area(protected) | Up to 5,500 m2/m3 |

| Bulk Weight(net) | 165.00 kg/m3 +-2% |

| Color | Not colorized,color originates from the raw material |

| Shape | Round,paraboloid |

| Pore system | May vary due to raw material |

| Material | PE re-granulate |

| Diameter | 30.0 mm |

| Material thickness | Approx.1.1 mm |

| Specific gravity | Approx.0.95 kg/I(without biofilm) |

| Note | The ALternative to the Transchip 3.0 made from virgin PE material |