Mechanical Screen

Municipal & Industrial wastewater treatment plants generally use mechanical screening as the first step in the wastewater treatment process (pretreatment), Mechanical screens remove larger solids from wastewater in order to protect the equipment in the treatment stages that follow.

The type of screen most suitable for a particular application relates specifically to the size and type of solids in the wastewater. For example, sticky solids may require the use of a drum screen, while larger solids may just require a standard screw screen.

We offer a complete range of mechanical screens, from automatic coarse bar screens, to drums screens and screw screens. We also offer specialist compact screen units that facilitate the combined removal of sand, oil, grease, fibers and solids all in a single process step.

All of our mechanical screens are supplied from our Pune factory.

In comparison to many other mechanical pre treatment systems in the market, our mechanical screens have unique selling points and advantages. These include higher treatment efficiencies, triple seals to prevent any bypass of wastewater, and fully automatic operation with custom built control panels and sensors. Choosing the right screen is the first step for successful wastewater treatment and ensures the protection and continuous operation of the downstream assets. Our range of mechanical screens can be integrated into any existing onsite infrastructure, and they can even be installed within existing pump stations.

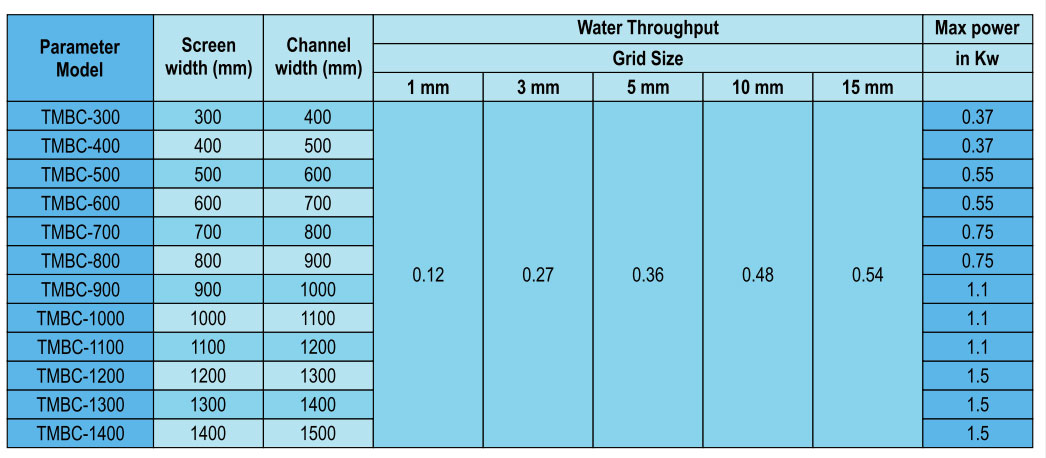

Specification :

Features :

In comparison to many other mechanical prel reatment systems in the market, our mechanical screens have unique selling points and advantages. These include higher treatment efficiencies, triple seals to prevent any bypass of wastewater, and fully automatic operation with custom built control panels and sensors. Choosing the right screen is the first step for successful wastewater treatment and ensures the protection and continuous operation of the downstream assets.

Our range of mechanical screens can be integrated into any existing onsite infrastructure, and they can even be installed within existing pump stations.

Mechanical Screen Details

- Manufactured with world-class components

- Punched hole or bar

- 304 or 316 SS options

- All components manufactured in strict quality

- control in factory

- Can operate in temperature range: -15 to 50°

- 1mm to 25mm screen size options

Advantages :

- Removal of large solids from wastewater [large food pieces or grit/stones]

- Removal of fibres from industrial wastewater [typical in pulps]

- Removal of fine solids from wastewater [sand, small food particles]

- Combination removal of fat, oil, grease, sand, solids and fibres from wastewater

- Municipal waste water treatment plants

- Municipal Pump Houses

- Bakery wastewater treatment

- Pasta processing and manufacturing

- Distillery wastewater treatment

- Potato chip/crisps factories

- Slaughter houses/abattoirs/meat processing plants

- Grit removal

- Vegetable processing

- Industrial solid separation

- Any type of processing that produces waste with solids