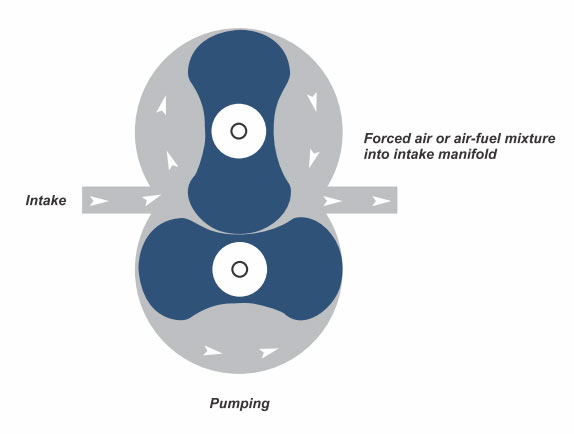

A Roots blower with two-lobed rotors.

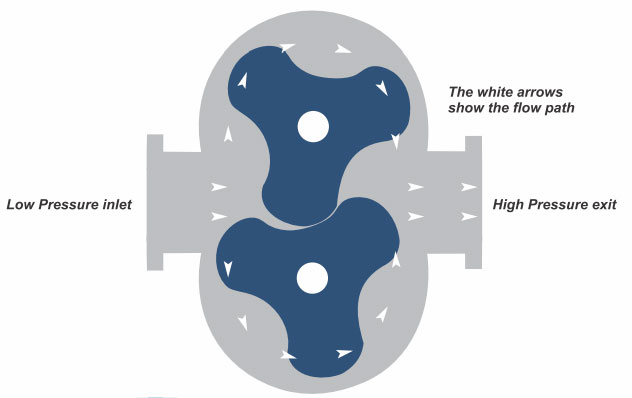

A Roots blower with tri-lobed rotors.

Rootx Blower Mechanism

The Roots-type blower is a positive displacement lobe pump which operates by pumping a fluid with a pair of meshing lobes resembling a set of stretched gears. Fluid is trapped in pockets surrounding the lobes and carried from the intake side to the exhaust.The Roots is a valve less positive displacement mechanism in which a pair of lobed rotors, interlocked and synchronized, rotate in opposite directions moving past each other and the stator wall with small clearance.AIR/Gas is trapped in front of each lobe and swept around the stator periphery from inlet to outlet.Very large displacement (above 20000 m3/h) and the mechanism has proven very effective in thpressure region from 10 to 103 mbar, but only when delivering against low pressure differentials.As a displacement machine and not a true compressor, the foots mechanism is not suited to discharging to near atmospheric pressure (i.e with significant differential pressure).

FEATURES

Roots blowers stand to be one of the most basic needs of the sewage and effluent treatment plant, thus is most important aspect for all the stake holders. Most neglected & yet to say most sought after area for many suppliers and becomes most fragile and most vulnerable area too...Such is the position of the roots blower and still we have something more to offer...We offer precision, robust, efficiency, long life, yet economical roots blower for all stake holders right from smallest of 35 m3 to presently 10000 m3/hr.

Hence ROOTX becomes the end of the trial era and beginning of the performing machines. X stands for Xtra care, Xtra engineering, Xtra precision, and X means just two letters before the end of the Alphabets...meaning nothing left to explore... We stand by our word Xtra...and we deliver the product as a SERVICE..

WE WELCOME YOU ALL FOR THIS SMOOTH AERATION Xperience....

Advantages

- Manufactured with state of the art technologies, Shortest deliveries,

- Rootx available in both vertical and horizontal

- The compact design & engineered for continuous service when operated in accordance with speed and pressure ratings.

- Antifriction bearings, roller bearings - a standard feature for all blowers

- Air blowers is available for flow rates from 25 m3/hr to 10,000 m3/hr in single stage

- Ready to install or as bare blower units, for replacement.

- Improved volumetric efficiency and reduced operating temperature

- Splashed oil lubricated with spur timing gears

- Balanced machined twin lobe impellers