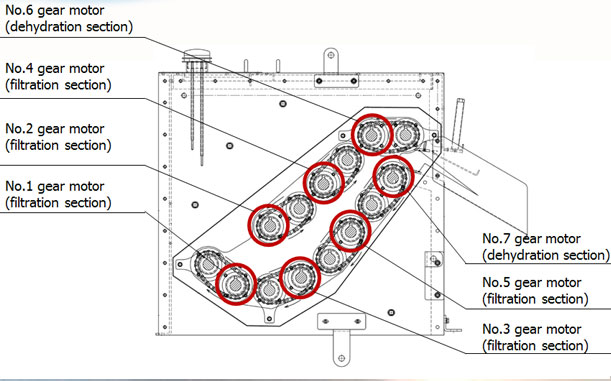

Special Features:

- Compact and easy to install

- Possible to treat oil-contained sludge

- Energy saving

- Low wash-water consumption

- No secondary pollution

- Simple maintenance work

- Hardly to clog

Applications

- Excess sludge from packaged sewage treatment equipment, wastewater treatment plants, livestock wastewater treatment plants, and industrial wastewater treatment plants

- DAF (=Dissolved Air Floatation) froth including oil-contained sludge

- Coagulation settling sludge

- Sludge made by the mixture of above sludge

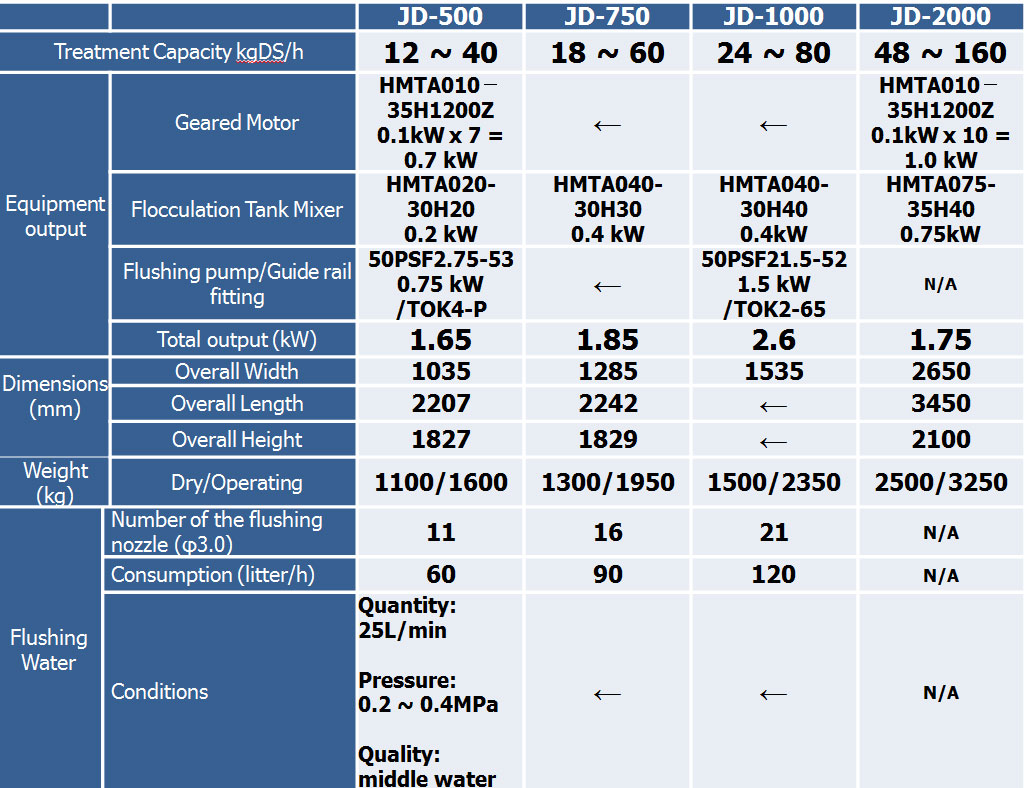

Structure of JD series -1

Number of filtering rollers, each of which consists of a stainless steel shaft and multiple thin discs, are placed in two rows, upper and lower. The rollers close to the sludge inlet form the filtration section, and the rollers closed to the outlet form the dehydration section.

Structure of JD series -2

Number of filtering rollers, each of which consists of a stainless steel shaft and multiple thin discs, are placed in two rows, upper and lower. The rollers close to the sludge inlet form the filtration section, and the rollers closed to the outlet form the dehydration section.

Structure of JD series -3

Number of filtering rollers, each of which consists of a stainless steel shaft and multiple thin discs, are placed in two rows, upper and lower. The rollers close to the sludge inlet form the filtration section, and the rollers closed to the outlet form the dehydration section.

Structure of JD series -4

Structure of JD series -5

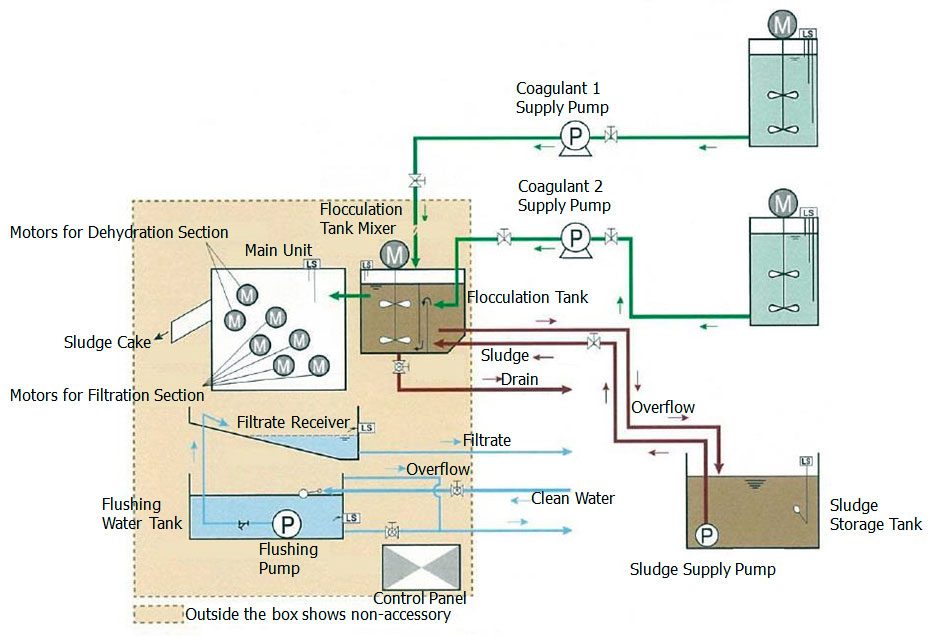

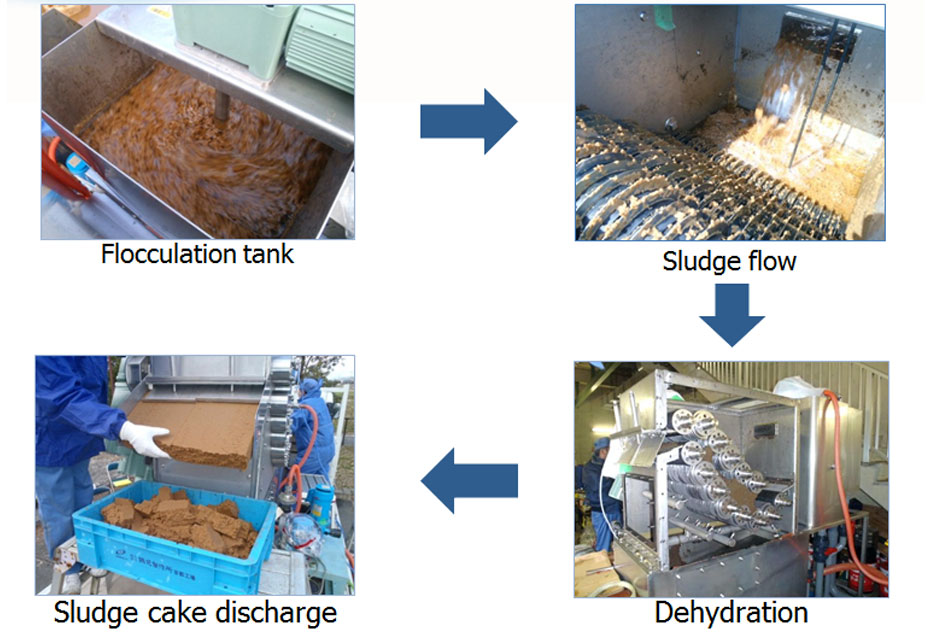

Basic flow chart

Dehydration flow

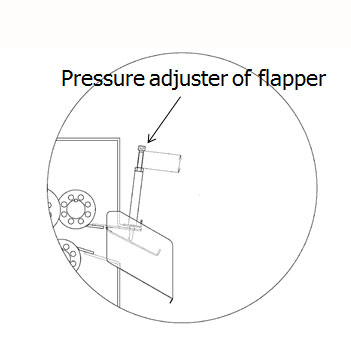

Operation adjustment -flapper

- Adjust pressure adjuster of flapper for the suitable dehydration. Adjust it in the range between 0 - 40 mm depending on situation.

- When screwing up to the end, it becomes to be max. 0mm. Standard pressure adjustment is 20mm.

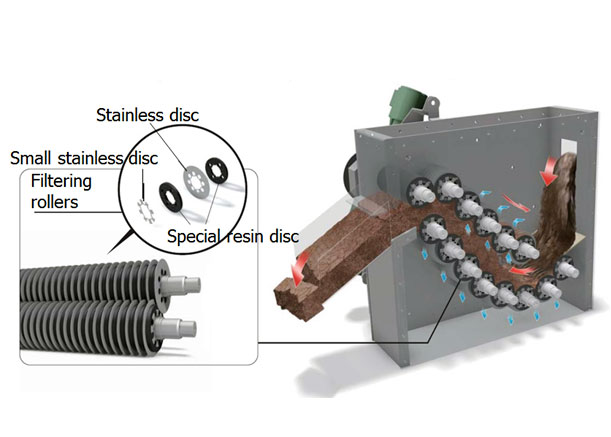

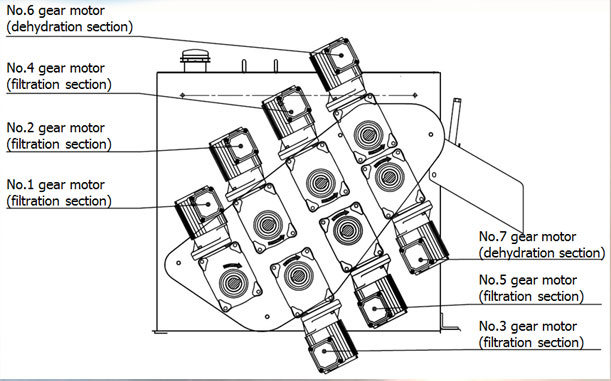

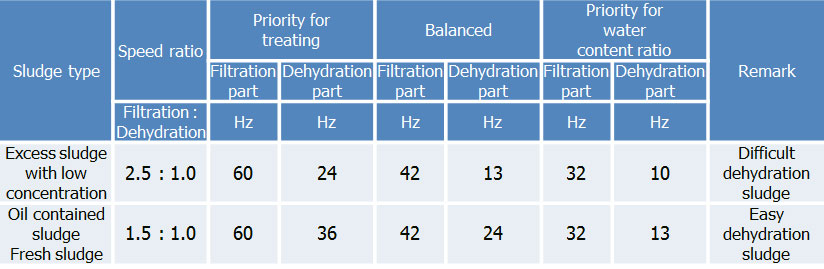

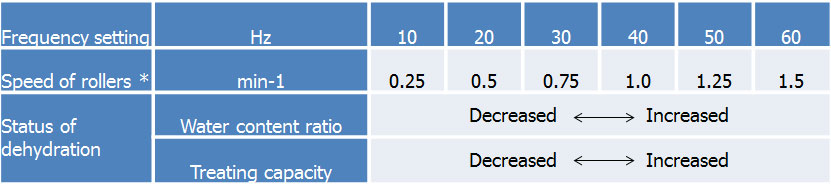

Recommended operation setting of inverter for rollers

Filtration part: driven by No.1~5 gear motor

Dehydration part: driven by No.6~7 gear motor

* refer page Structure of JD series -5

Speed of rollers (Reduction gear ratio 1/1200) * Speed of rollers is theoretical value

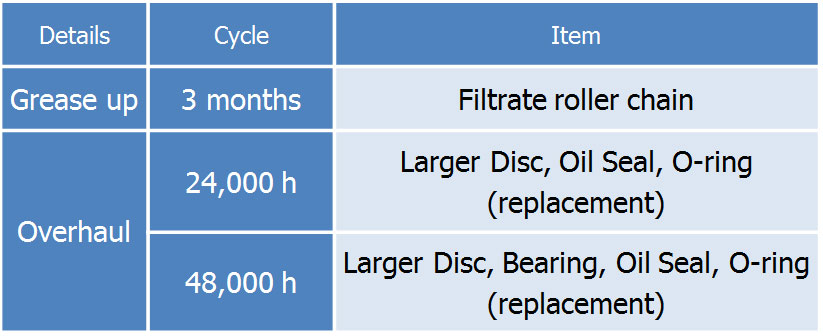

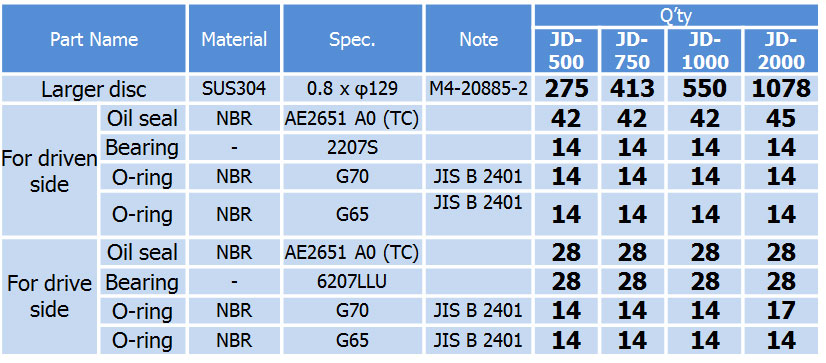

Routine Maintenance & Overhaul -1

Main dehydration section

Routine Maintenance & Overhaul -2

Patent application country

(during the application and patent acquisition finished)

Japan, China, Hong Kong, Taiwan, Malaysia, Thailand, Singapore, Vietnam, India, Russia, Ukraine, Europe (The Netherlands, Česká republika, Slovenská Republika ), Australia, Republic of South Africa

Point of Patent *Please refer attached handout

Fig. 3: Constitution of the disk

Assembling is possible easily at low cost by interposing smaller disc and larger disc on the protuberance of PPS-resin precision ejection molded article.

Fig. 4: Bigger disc is possible to sliding

This constitution makes it possible to prevent clogging of the filtration gap with effect.

Comparison Multi-Disc Dehydrator & Multi-Disc Screw Press Dehydrator

Multi-Disc Dehydrator – JD series

- Can treat the sludge with high concentration(0.5~5%)

- Can treat the various kinds of sludge

- Can treat the organic sludge containing inorganic sludge

- Sludge Cake will not be blocked out

Multi-Disc Screw Press Dehydrator – MDQ / MDC series

- Mount the multi-shaft

- Easy Maintenance

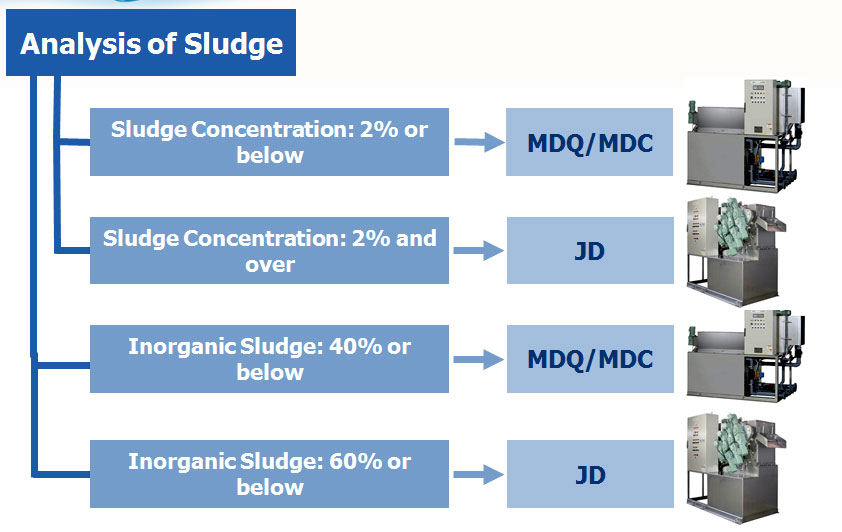

Criterion of Selecting the Dehydrator

Possible to Treat the various kinds of sludge

Wastewater Treatment Plant, Food Factory,

Livestock Farm and others.

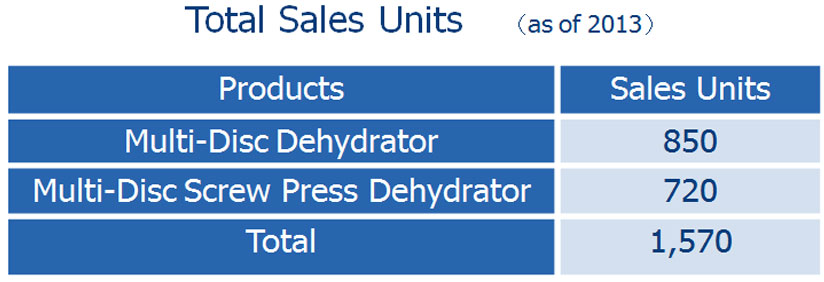

Total Sales are 1,570 units.

JD-500 at Brewery Factory

JD-1000 at Food Manufacturing Factory