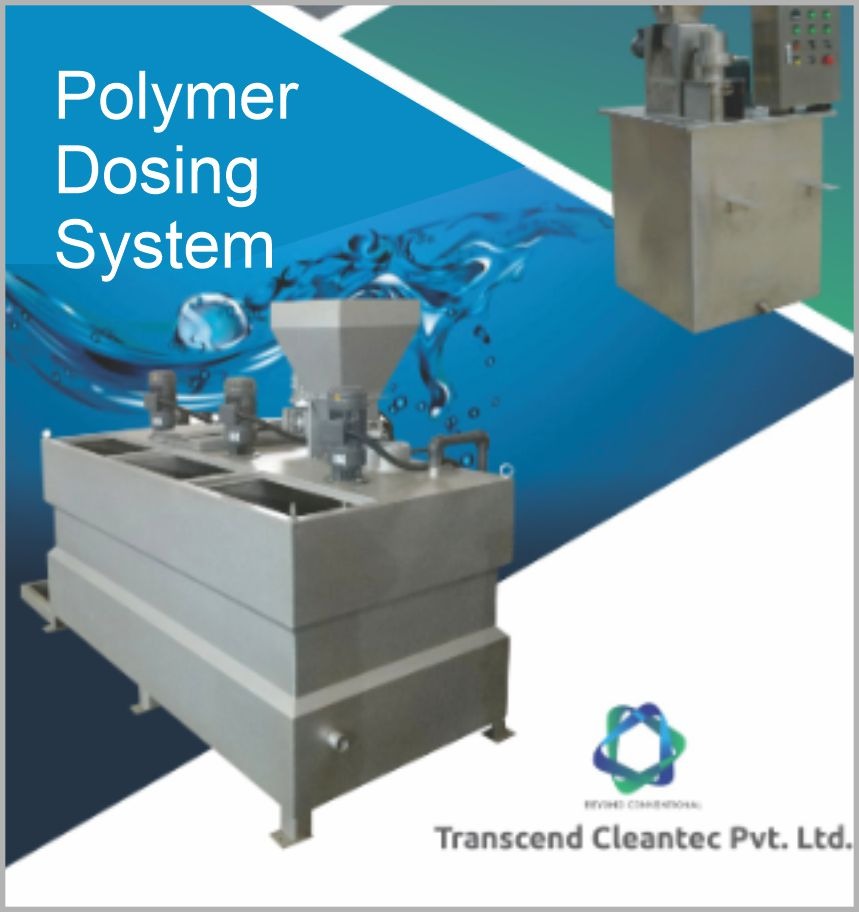

Polymer Dosing System

The Polymer Dosing System is used widely in the water and wastewater treatment industry for the activation, blending and dosing of polymer as a solution. Its low price and exceptional qualities make it a very attractive and affordable system. The Polydos product is in a series of simple and flexible as well as commercial and effective preparation systems for polymers. The range of product covers in between 1 to 3 and associate with both dry and liquid polymers, the systems are equipped with specific water and level material to secure efficient and economic operation of the systems. Prepared polymers are used to achieve coagulation and flocculation that means particle removal in both drinking water and waste water treatment. Also, polymers are efficient sludge in dewatering applications.

The Polymer Dosing System is the mixing equipment which used for the preparation of working solutions or stock solutions of chemicals (both dry and liquid polymer), the whole process is automatic, safety and continuously. It provided to have the advantage of good treatment result, high automation level, easy to operation and management, less occupied area, compact size and convenience in transport, which only need water and electrical source on the scene. During the running, the polymer dosing system fully complies with consistent, stable and safety operation. The surface that direct contact with the medium is made of engineering plastics and stainless material and it improve srust resistant. The polymer dosing system is suitable for powder (Powder Dosing System), fiber and other material which difficult to melted, easily caked and high standard of dosing requirement, it also applies to matching and dosing the liquid material.

Automatic Poly Dosing System

The Automatic Poly Dosing System permits the preparation maturing and the amount of the granulated poly electrolyte to be carried out automatically in a continuous manner. The automatic poly electrolyte preparation and dosing unit composed of a rectangular tank divided into three sections.

The first section, for dilution, is complete with polyelectrolyte loading hopper, micro-screw better and relevant variable speed drive, fast stirrer for the polyelectrolyte mixing, inflow system for the dilution water and relevant solenoid valve, flow meter and pressure relief; the second section, for the polyelectrolyte mixture ageing, is equipped with slow stirrer and bottom suction and drain system. The third section, for ageing and storage, is used for the mixture storing and is provided with slow stirrer and suction and delivery system for the polyelectrolyte solution.

Polyelectrolyte Dosing

Polyelectrolyte dosing pump contains of solution preparation, tank accompanied by dosing tank. Poly electrolyte dosing system is designed under the strictest caution of experts. It is tested by using the latest techniques to ensure that it is free from all kinds of defects.

Poly electrolyte dosing can also be used to impart a surface charge to neutral particles, enabling them to be dispersed in aqueous solution. They are therefore often used as thickeners, emulsifiers, conditioners, clarifying agents, and even drag reducers. They are used for water treatment and in oil recovery. Polyelectrolyte helps in better Flocculation due to its special characteristic of captivating micron size particle and to form a heavy flow. This is a latest innovation in the field of Filtration. The main purpose of providing polyelectrolyte dosing after coagulant dosing is to achieve better Filtration to make effluent as clear as possible.