Sludge Dewatering

Sludge dewatering is the process of separation of components of solid and liquid sludge to minimize the sludge disposal. There are many techniques available for Sludge dewatering which includes drying beds Filter press, Belt press, decanter, centrifuge & latest & advanced being Sludge dewatering press. Sludge dewatering equipment is not intended to treat the sludge or liquid but; it only separates the liquid components & solid components so it will get easier & cost-effective to handle the separate phases of the disposal. Once the final sludge has been dewatered, then the liquid is treated in ETP/STP & solid sludge is disposed.

The main purpose of the Sludge dewatering machine is to minimize handling and disposal. Sludge dewatering press is the most cost-effective method of dewatering and hence helps to sustain the environmental objectives of the company. Basically, both the public & private sectors are required to dispose the sludge which is approved by industries. Sludge dewatering is totally focused on the reducing weight as well as volume of sludge & also on cost & transportation services. First step of Sludge dewatering is removing water from it so by removing water it will impact on reducing volume & weight of sludge.

Sludge dewatering press

Sludge dewatering press is treatment which generates dewatered cake with high dry solid content and a quality of cent rate water, leading to vital sludge volume reduction. So, that’s why the prices which are related to sludge dewatering screw press have been decreased. With its long industrial expertise, dewatering Industries is your resolution supplier and sludge screw press manufacturer for cost-efficient Sludge Dewatering, to manage a large vary kinds of sludge. That being a foresaid, the multiplate sludge dehydrator,unit is appropriate to handle each biological and physical-chemical kinds of sludge. Transcend Cleantec Pvt. Ltd. Is a one of best manufacturers of sludge dewatering Screw equipment, Transcend has been on the fore front and has been pioneer of such machines manufacturing in india.

Transcend has been market leader with succefully supplying and commissioning Sludge about 100 machine to varies industries Businesses and municipalities trust us, as a result of they know that our commitment & value driven manufacturing approach we have produced superior sludge dewatering screw press in India…MADE IN INDIA Transcend’s Multi-disc sludge press utilize both gravity filtration and screw compression techniques Transcend’s Multi-disc screw press dehydrators can cope up with a wide range of sludge concentrations from 0.2% to 10%, and also stably can dewater sludge that has high oil content.

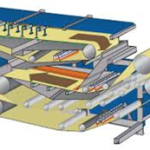

Multidisc are arranged one after other with alternate disc being moving and fixed. The gap between the plates acts as media for fine filtration. The screw press main unit requires very very low power motor and the filtration surface area consists of a multiple discs which are self-cleaning, and generally do not clog, thus, the sludge press can be used continuously. The main unit of the sludge dewatering screw press is of multi-shaft design. Hence, when two or more main units are configured into one machine, any individual shaft can be repaired or serviced without interrupting operations.

Benefits for Customers :

- It is efficient & versatile press style with resolution

- Automatic laundry system, reducing operational period

- Low footprint

- Low flocculent consumption

- Low energy consumption

- Low maintenance

- There is no would like of pre-dewatering

- It will cut back sludge volume with typical dry solids content of two hundredth

- Solids capture of over ninety fifth, reducing filtrate treatment value

- Adaptable to native necessities and conditions, many units with totally different sizes are out there

Applications :

- All range of industries ETP & STP

- Faecal Sludge management

- Primary sludge and biological sludge dewatering

- Wastewater treatment plants – New / Existing

TOP view of the screw unit with multi discs arranged

Also the pitch of the screw flight is gradually increasing making the valley / volume available for the sludge narrow towards the outlet so that flocculated sludge that is concentrated by gravity filtration is further dewatered by compression.

Inbuild flocculation tank with mixer

- Transcend’s Multidisc sludge dewatering screw press is integrated with sludge flocculation tank which efficiently mixes the input sludge with the optimal dose of flocculation. This flocculated sludge then enters the screw body which in the initial stage has more open area to dewater the separated water faster.

- As screw rotates at a rpm which is set to give optimum output carries the dewatered concentrated sludge forward towards the end. As screw is been gradually increasing making the valley / volume available for the sludge narrow towards the outlet so that flocculated sludge that is concentrated by gravity filtration is further dewatered by compression.

Comparison between Multi Disc Screw Press v/s Filter Press

Multi Disc Screw Press

- Simple arrangement.

- Maintenance is easy.

- Long life of discs.

- Low maintenance and maintenance costs.

- No clogging. Cleaning is automized and is easy.

- Simple and short start-up and shut down procedures.

- No external lubrication system is required.

- Flocculator is inbuilt in the Screw press

- Continuous operation. Hence continuous output can be obtained. Process can be automized.

- Only electricity and water supply for cleaning is required, and that too in less amount.

- For a multi-channel machine, one or more channel(s) may be removed for maintenance purposes, while the machine with the remaining channel(s) may still be operated.

- Low Power Consumption:Low installed HP and reduced power consumption due to simple arrangement.

Filter Press

- Intricate and huge structure.

- Maintenance is complex.

- High maintenance and maintenance costs.

- Filter cloth has to be replaced frequently

- Filter cloth can get easily clogged. Hence manual cleaning and clogs removal has to be done frequently.

- Time consuming process.

- External lubrication system may be required.

- Intermittent operation. Intermittent output. Process automization is difficult.

- Compressed air, oil for hydraulic power packs are required in addition to electricity, for operation of the machine. Fluctuations in air or oil supply can easily affect the functioning of the machine.

- Flocculator needs tp be procured separately adding to the overall cost.

- The whole machine is in operation or is shut down.

- High Power Consumption :Intricacy in the structure demands more power.

Comparison between Multi disc Screw Press & Decanter Centrifuge

Multi Disc Screw Press

| Simple : Low maintenance. |

| Low speed: No (or very low) live floor loads. Nothing special is required. |

| Reduced noise: Nothing special is required. Acoustic protection is not required. |

| Vibration and temperature: Monitoring is not required for the Screw Press. |

| Low Power Consumption :Low installed HP and reduced power consumption |

| Reduced installation costs for the electrical connection. |

| Simple and short start-up and shut down procedures. |

| Frequent stops and starts are possible. |

| In the event of an eventual shut down, repairs can be completed at the waste water treatment plant by regular mechanics. |

| For a multi-channel machine, one or more channel(s) may be removed for maintenance purposes, while the machine with the remaining channel(s) may still be operated. |

| Vibration analysis and preventative maintenance are not critical |

| The Screw Press includes a flocculator with a variable speed agitator to optimize flocculation and polymer dosage, which most likely results in a reduced polymer consumption. |

| More reliable:Very few components of the Screw Press reduce the possibility of catastrophic shut down of the equipment due to its low speed and simple design. |

| The effects of grit are greatly reduced in the slow-moving Screw Press. |

| No external lubrication system is required. |

| Low maintenance cost. |

Decanter CENTRIFUGE

| Simple :High maintenance. |

| High speed:High live floor loads. Building needs to be designed especially to deal with these loads. |

| High noise: Noise attenuation is required as part of the building construction. |

| Vibration and temperature: Monitoring of the electric motor, bowl and scroll is very critical. |

| High Power Consumption :High installed HP and high power consumption (around 20 times more than screw press). The additional power cost over the life of equipment is very significant. |

| High installation costs for the electrical connection. |

| More complex and lengthy start-up and shut down procedures. Bowl may continue to rotate for a while after shut down. |

| Frequent starts and stops are not possible. |

| In the event of a shut down, the centrifuge may have to be shipped to the manufacturing plant for specialized repairs. The centrifuge may require visits from specialty mechanics. |

| The whole machine is in operation or it is shut down. |

| Vibration analysis and preventative maintenance are very critical. Additional training of plant personnel may be required. |

| Flocculation takes place inside the centrifuge and cannot easily be controlled, and may result in a higher polymer consumption and higher annual expenditures. |

| Less reliable:Many more components may cause a shut down due to the high speed and high power. |

| The centrifuge may be affected by the presence of grit in the sludge in the form of unpredictable premature abrasion wear. |

| External lubrication system is usually required. |

| High maintenance cost. |

Comparison between Multi disc Screw Press & Belt Press

MULTI DISC SCREW PRESS

- Labour costs: The Screw Press requires little attention. Continuous unmanned operation is possible.

- Spare requirements: Less

- Maintenance costs: Maintenance is less frequent, simple and easy. Hence semi skilled operators can also perform the operation easily.

- Most maintenance can be performed by one person.

- Equipment is very simple and reliable.

- Wash Water: Very less wash water is required.

- Capture Rate: A high capture rate is fundamental property of the Screw Press and frequent adjustment is not required to maintain it high.

- Operation: Simple and adjustments are very easy.

- Partial operations: For a multi-channel machine, one or more channel(s) may be removed for maintenance purposes, while the machine with the remaining channel(s) may still be operated.

- Shut-down procedure: Shut down procedure is easy. Frequent shut-down and start-ups are possible.

- Total maintenance and operation costs: Low

- Flocculator is inbuilt in the Screw press

BELT PRESS

- Labour costs: To properly operate, it requires constant adjustment and attention. Hence it is labor intensive

- Spare requirements: More – Higher initial investment in building space.

- Maintenance costs: Many parts (bearings, belts, doctor blades, shafts, etc) require frequent maintenance and adjustment, and can cause frequent shut down of the machine. Requires skilled and trained operators

- The complex equipment can easily become unreliable.

- Wash Water: The requirement for wash water is substantially high.

- Equipment to pre-treat this water may be required.

- This wash water supply consumes high power and needs to be considered in the overall analysis.

- This wash water poses an additional load on the plant since it is sent to the head works.

- Capture Rate: The capture rate may not be very good

- It depends how close the BELT PRESS is being operated to the optimum conditions.

- Analysis of the capture rate needs to take into account both filtrate and wash water.

- The solids from the filtrate and the solids from the wash water pose additional substantial loads on the plant.

- Operation: Not so easy especially for inexperienced operators.

- The BELT PRESS requires continuous online adjustment.

- Partial operations: The whole machine is in operation or it is shut down.

- Shut-down procedure: More time to wash down the belts and structural components of as required for a hygienic environment.

- Total maintenance and operation costs: High

- Flocculator needs tp be procured separately adding to the overall cost.

Comparison between Multi disc Screw Press & Sludge drying beds

Multi Disc Screw Press

| Space requirements: Requires very less space |

| Operation: Runs 24×7 throughout the year. |

| Mobility: Can be moved to different locations, if required. |

| Capture Rate: A high capture rate is fundamental property of the Screw Press and frequent adjustment is not required to maintain it high. |

| Working: Can work continuously automatically. |

| Maintenance: Maintenance is easy |

| Sludge Cake: Obtaining sludge cake is easy and automatic |

| Flocculator is inbuilt in the Screw press |

Sludge Drying Beds

| Space requirements: Requires very large space |

| Operation: Unreliable in rainy and cloudy seasons. |

| Mobility: Once constructed, cannot be moved. Needs to be demolished and reconstructed. |

| Capture Rate: The capture rate is very less. |

| Capture rate depends upon the bed media. However there are high chances that the sludge passes through the media without the solids being captured and the filtrate may contain huge amount of solids. |

| Working: Can work only up to the holding capacity of the beds. |

| Works in batches. |

| Maintenance: Maintenance is cumbersome. |

| Sludge Cake: Sludge cake has to be removed manually and is cumbersome. |

| Flocculator needs tp be procured separately adding to the overall cost. |